A solar-savvy house and the ties that bind

limit testing

Michael Stoner, who graduated with a B.S. in civil engineering in May, has been working with Dustin Albright to test the structural system. Here, in a Clemson engineering lab, he uses a shear-wall frame to shove the top of a wall structure until it racks and fails. Results from tests like these have helped him identify weaknesses in the structure’s joints and recommend improvements.

The testing itself is tricky, because the curving joinery of the Indigo Pine system doesn’t offer the usual flat surfaces of an ordinary two-by-four. Stoner has had to figure out where and how to apply the force to get reliable results.

“But I’m confident we’ll get the results we need,” he says. “There’s a learning curve in how you build the walls, and there’s a learning curve in how you test them.”

Stoner grew up building and admiring wood-frame houses. But he has noticed, in the destruction of tornadoes and hurricanes, that conventional structures don’t always measure up. He took an interest in the durable strength of cross-laminated timber, a specialty of Dustin Albright, and plans research on that topic. Plywood, which also derives much of its strength from lamination, makes sense in the Indigo Pine system, Stoner says, because it’s “an alternative to wood but still uses wood, in maybe a smarter way.”

Albright, who helped the Indigo Pine team develop and evaluate the structure, says the system scores high on ductility—a building’s ability to flex and absorb energy, including the forces of high winds or earthquakes. “Each stainless-steel cable tie can take around two hundred and sixty or sixty-five pounds of tensile force before it gives,” he says. “And because there are so many of them, there’s a lot of redundancy in the system.”

Albright plans to continue research and development on the framing system, which is designed with South Carolina’s wood-products industry in mind. “We’re working with industry in the state to continue to develop the system,” he says. “And who knows, we may even bring it to market.”

Photo of Michael Stoner by Ashley Jones.

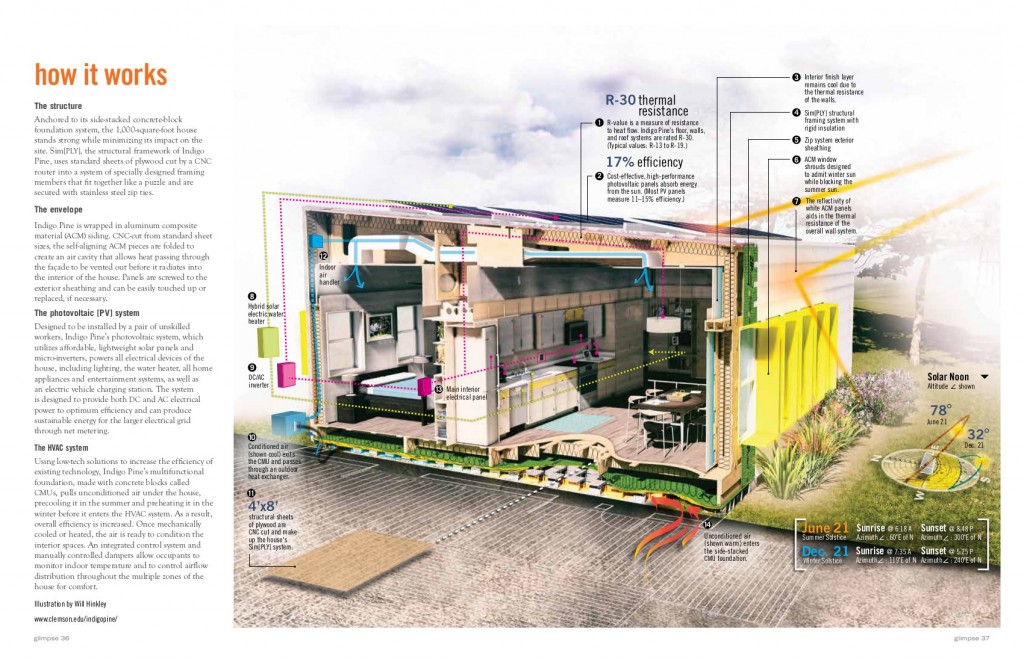

The ingenious structural system, called Sim[PLY], was invented in the studio with help from Clemson student engineers. It uses puzzle-like interlocking pieces cut with a computer-guided cutter known as a CNC. The system allows the team to email a house, because the structure is built on computers for quick assembly on site.

Photo by Neil Caudle.

For Indigo Pine East, the estimated cost is between $250,000 and $270,000, Clair Dias says. But some of that cost was incurred in the testing and tweaking unique to a prototype. “We would love to bring the cost down to two hundred thousand or maybe two-twenty,” she says. “That would make the house affordable for more families, especially if they could do some of the work themselves.”

The Solar Decathlon

In the U.S. Department of Energy Solar Decathlon, collegiate teams design and build energy-efficient houses powered by the sun. These teams spend almost two years creating houses to compete in the ten contests of the Solar Decathlon. The winning team produces a house that:

- Is affordable, attractive, and easy to live in

- Maintains comfortable and healthy indoor environmental conditions

- Supplies energy to household appliances for cooking, cleaning, and entertainment

- Provides adequate hot water

- Produces as much or more energy than it consumes

The competition includes ten contests:

- Architecture Contest (juried)

- Market Appeal Contest (juried)

- Engineering Contest (juried)

- Communications Contest (juried)

- Affordability Contest (juried)

- Comfort Zone Contest (measured)

- Appliances Contest (measured)

- Home Life Contest (measured)

- Commuting Contest (measured)

- Energy Balance Contest (measured)

Teams entered in the 2015 competition:

- California Polytechnic State University, San Luis Obispo

- California State University, Sacramento

- Clemson University

- Crowder College and Drury University

- Missouri University of Science and Technology

- New York City College of Technology

- State University of New York at Alfred College of Technology and Alfred University

- Stevens Institute of Technology

- University of Florida, National University of Singapore and Santa Fe College

- The University of Texas at Austin and Technische Universitaet Muenchen

- University at Buffalo, The State University of New York

- University of California, Davis

- University of California, Irvine; Chapman University; Irvine Valley College; and Saddleback College

- Vanderbilt University and Middle Tennessee State University

- West Virginia University and University of Roma Tor Vergata

- Western New England University, Universidad Tecnológica de Panamá, and Universidad Tecnológica Centroamericana

- Yale University

—U.S. Department of Energy

www.solardecathlon.gov

Alison Martin, Indigo Pine’s health and safety officer, runs through a checklist on day one of construction. She says the project has given her the real-world experience employers value. “Before this project, I’d never dealt with OSHA, or any site safety issues,” she says. “We’ve had a lot of training that will help us get jobs later on.” Photo by Neil Caudle.

Photo by David Pastre.

Photo by David Pastre.

Cooking up a new kind of kitchen

Indigo Pine’s DNA has already found its way into another kind of structure, a kitchen to help South Carolina farmers turn produce into market-ready food.

David Pastre teamed up with Harry Crissy to launch a series of “Crop Stops,” USDA-approved kitchens equipped with commercial-scale freezers, ranges, ovens, and other equipment for handling local produce. The project responds to research showing that farmers often have trouble marketing their produce locally because they aren’t equipped to meet standards set by restaurants and governments.

Crissy’s economic analysis revealed that existing commercial-scale kitchens tended to be few and far between, often too far away to make them useful to small farms. He reasoned that deploying a number of smaller, less expensive kitchens around the state would make processing more available, and more profitable, for many farmers.

The first Crop Stop opened this spring on John’s Island, in an old mobile home refurbished in Charleston and trailered to the site. The second edition, scheduled to open in Greenville this year, employs the Indigo Pine technology Pastre helped guide through multiple stages of development. “We’re applying the same simplified construction method to the new Crop Stop,” Pastre says. “We think of this as a replicable model, and there are plans to do a lot of these across the state.”

The Crop Stop in Greenville, like the original on John’s Island, will be managed by a nonprofit group. It can be moved by trailer and will feature a flash freezer that can reach negative forty-five degrees. Quick freezing helps prevent bacterial growth and retains about 80 percent of the nutrients in the vegetables, Pastre says.

“Usually, small farms can only sell only about fifty percent of what they grow, and the rest goes to waste,” Pastre says. “With a Crop Stop, the producers can still sell at the farmers’ markets, but whatever comes back they can process and freeze, and then sell that as well. Harry’s studies show that within three years they could be doubling their gross income.”

David Pastre is a senior lecturer at the Clemson Architecture Center in Charleston. Harry Crissy is an Extension agent in the Clemson Institute for Economic and Community Development. The Crop Stop project originated at the College of Charleston in a farm-to-school initiative funded by The Boeing Company.

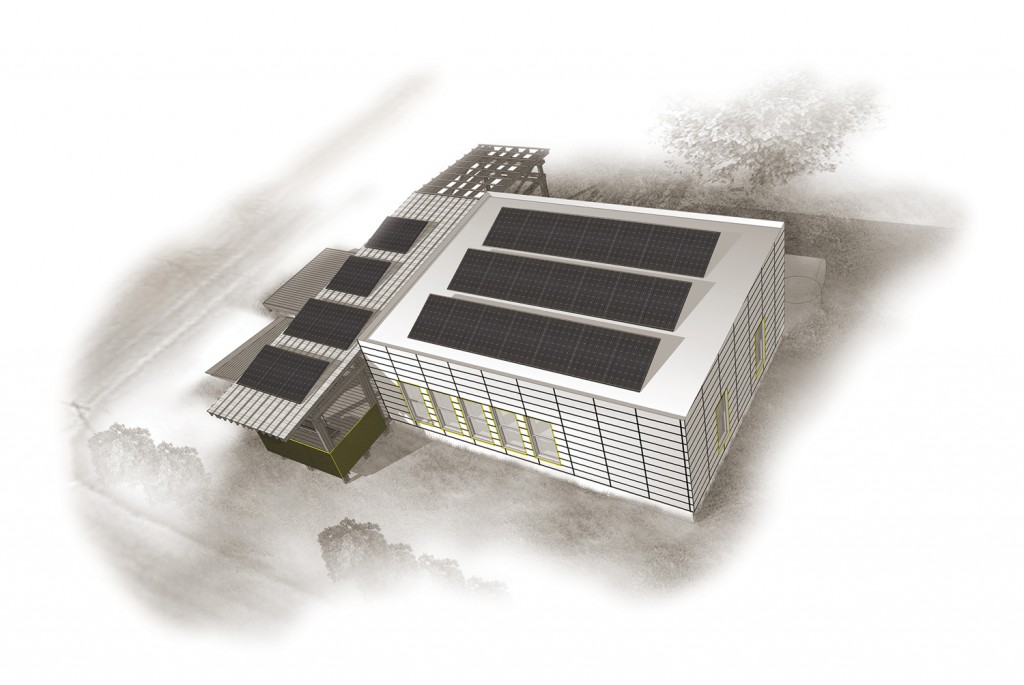

Renderings like this one, which shows Indigo Pine’s solar panels, were included in a packet of plans, specs, and data sent to the Department of Energy as part of the team’s entry in the 2015 Solar Decathlon. Illustration by Will Hinkley.

Indigo Pine East, a 1,000-square foot, three-bedroom prototype, nears completion in July. The first of two versions to be built by Clemson’s Solar Decathlon team, the house is open to visitors at the South Carolina Botanical Garden until the end of the year. Photo by Eric Balogh.

A national competition inspires a throng of young designers and builders to lead us back to the sun.

Almost four decades ago, I spent two years of weekends building a modest little passive-solar house on a five-acre woodlot in rural North Carolina. In winter, sunlight angled through a wall of south-facing windows, warming the pavers I’d laid for a floor. As we slept upstairs, the pavers surrendered their heat and kept us warm all night. The house was basic, simple shelter: comfortable, low-tech, and cheap. And it worked.

Two generations later, on a hot day in May, I strap on a hardhat and orange safety vest and climb a gently sloping ramp to investigate another kind of solar dwelling, this one from the future, not the past. The 1,000-square-foot house, a full-scale prototype under construction in the parking lot of the South Carolina Botanical Garden, is only slightly smaller than the 1,200-footer I built when I was about the same age as the graduate students I find balanced in the rafters this morning. And our goal was the same: basic, low-cost housing attuned to the sun.

But the houses could not have been more different. Mine was a shelter I pounded together with a twenty-two-ounce framing hammer. Today’s version is a futuristic machine for living, no hammer required. And the thirty-four photovoltaic panels on its roof will crank out two hundred and eighty-five watts apiece, enough to power not only the house but the family car.

So I feel a pang of envy, as I wander this half-finished space, for the people who conceived it. I envy their access to solar-savvy mentors, the ones I badly needed but couldn’t find. I envy their swift computers running algorithms, crunching data, and wielding all manner of graphical tools, with which the team has rendered, in three-dimensional models, the house and each of its thousands of structural parts. I envy their access to experts in engineering, forest resources, horticulture, landscape architecture, package design, social science, and more. But most of all, I envy their collective ingenuity.

I worked solo, designing my house. I found a sun chart for my latitude and some tables of data, enough to calculate the rate of heat gain through glass and the known thermal resistance of cedar siding, plywood sheathing, fiberglass insulation, and drywall. I memorized all of the relevant chapters of the residential building code (you could actually do that, back then). I found an architect to critique my drawings and an engineer to check my calculations. I gathered up every book, pamphlet, and article I could find about solar houses and how to construct them. But the sum of my reference material didn’t even fill a pasteboard liquor box. To the Indigo Pine team, the full extent of my knowledge back then was so elementary it would amount to the architectural equivalent of Fun with Dick and Jane.

A new take on an old idea

Solar-tempered shelter served humankind for thousands of years, until the advent of central heating, after which we came down with a case of collective amnesia. Stop by an old Carolina farmhouse sometime and consider its orientation. Most likely, you’ll find it shaded with porches on the south and west, and sheltered with windbreaks on the north. Generous porches extended the living space, welcomed the neighbors, and protected the walls from a blistering sun. Back then, working with Nature was essential, and any self-respecting builder knew it.

But by the time I was laboriously drawing umpteen versions of my house with a number-two pencil on grid paper (eight squares to the inch), most of that commonsense knowledge had vanished, at least from the libraries and bookstores I haunted. And much of what I did find to read turned out to be goofy or just plain wrong. Solar housing was a novelty, back then, the province of well-intentioned hippie builders who cobbled together odd, leaky shelters, hung ghost catchers in their drafty windows, and scoffed at the building code. I remember helping a potter friend roof his new house with sheets of rusted galvanized steel he’d salvaged from a barn. As we teetered on homemade wooden ladders, a thunderstorm boiled up and sent a flood of rusty rainwater plunging down the slope. We descended the ladders blood red from head to toe.

Alison Martin, health and safety officer for the Indigo Pine project, would not have approved. She has identified, analyzed, and quashed every conceivable workplace hazard. Tall, tippy ladders? No. Use the scissor lift instead. Long, frayed extension cords? No. Use the lithium-powered Bosch drills instead. The competition she and her classmates have entered requires them to comply with OSHA standards for job-site safety, Martin says, and that’s cool with her. “We actually have a webcam up there, so OSHA can weigh in on anything we’re doing on site,” she says, as if issuing a dare.

I didn’t have an Alison Martin on my job site. I was lucky to escape with my life, running a Skilsaw one-handed while I leaned way out from a rickety scaffold to trim the rafter tails. I remember risking the backs of my wife and several neighbors when they showed up to help me hoist the heavy beams that would support my second floor. It was pure, dumb luck that none of us wound up in the ER. One day, a hammer toppled off my stepladder and raised a big knot on my head. Another day, a sixteen-penny nail in a snow-buried plank pierced the sole of my boot and impaled my left foot.

On the Indigo Pine project, no one (knock on wood) has yet to suffer more than a splinter. Despite the fact that most members of the crew had never set foot on a construction site before March of this year, when they began assembling the full-scale prototype they call Indigo Pine East, no one has sawed off a digit or dropped a hammer on anybody’s skull. Mostly, the hammers have been idle, for lack of nails to drive. And the skulls? Encased in hardhats.

That doesn’t mean that the workers don’t weather some risk. But they are learning to communicate as builders do, with pithy signals that keep the work safely on track. While I’m poking around on the site, Eric Balogh, a second-year graduate student in architecture and a construction manager on the project, is perched on a scaffold with a partner, wrestling a joist into place. To align it, the partner shoves his end of the joist too abruptly, tipping Balogh off balance. “Dude,” Balogh says, regaining his footing, “you gotta warn me before you do that.”

That’s the sound of teamwork, and the Indio Pine team will compete, just as Clemson’s athletes do, with other schools. The occasion is a competition called the Solar Decathlon, sponsored by the U.S. Department of Energy (DoE), and it culminates this fall, when the students will spend nine days assembling the house in Irvine, California, followed by ten days of on-site monitoring and judging, October 8 through 18. In this competition, Clemson will not be the biggest school, the richest, or the highest ranked. But the Indigo Pine team has a tactical advantage, a not-so-secret weapon: They can email their house.

Yes, you read that right. The house can move by email. In fact, the original plan was to email Indigo Pine all the way to California, where a computer-guided router, known in the trade as a computerized numerical control (CNC) machine, would have configured its pieces from locally sourced plywood. But the team found a company in Charleston—Fine and Small Homes—with the CNC equipment and expertise to do the job. Having a South Carolina company on the project will improve the chances that Indigo Pine’s email-ready construction techniques will spread across the state, team members say.

When I first heard this claim about email, I was skeptical. Everybody knows you can’t email a house. But Balogh set me straight. As he puts it, “Planning the house is ninety percent of the job. Assembling it is about ten percent.” In a very real sense, the team has built its house in the studio, on computers.

Clemson can’t teleport its workforce along with its house, so the team will pack their tools and hardhats into a trailer and tow it across the country in a caravan to Irvine, California, where the pieces of Indigo Pine West will be waiting, bundled and stacked like so many plywood Legos, ready for someone to plug them together.

A thrill, right down to the bones

Now here’s where I ran into trouble with the concept, at first. Not having been raised as a member of the Lego generation, I am still rather fond of conventional framing, with lumber and nails. Toenailing with a hammer is a hard-won skill I won’t easily consign to obsolescence. Why futz around with sheets of plywood that a computer cut like paper dolls? Where’s the blade-spinning, resin-scented, hammer-pounding thrill of that?

It’s a different kind of thrill that these students are after: the thrill of the new. With their professors, including Dan Harding, whose architecture studio has become the team’s home field, they have figured out a way to make a house stronger, greener, and easier to build. They have invented an ingenious system for interlocking sturdy plywood shapes, belting them together with zip ties, and fitting them into the orderly bones of a house.

Walking around in this unfinished space, with all of its bones exposed, I have to admit I can see the appeal. The structure is already routed for wiring, plumbing, and ducting, with almost no drilling or cutting required. And strength? I give the wall a shove; it doesn’t even flinch.

Clair Dias, a graduate student in architecture who presides with considerable aplomb as the project’s manager of external relations, explains how the prototype I’m touring came together. Digital files created in the studio found their way to a Universal Forest Products plant in Salisbury, North Carolina, where a CNC cutter carved the slabs of plywood into shape.

“Every single piece has its own unique number, cut into it by the CNC machine, and that corresponds to our digital file,” Dias explains. “So if you need to know the next piece that goes in, you can go right to the computer, click on that piece in the model, and find the number you’re looking for. And if you show somebody how to do it one time, they can automatically look at a piece and sort of assume what it needs to fit into.”

The system is frugal. Remnants of plywood removed at the mill are recycled there, eliminating the mountains of scrap you find on other building sites. “Our biggest source of waste is actually the excess stainless steel ends from our zip ties,” Dias says. “You hook ’em in and cinch ’em down with a zip-tie gun, and it snaps off the excess stainless steel once you get to the right tension. So that’s our biggest waste item—a quarter-inch-wide piece of stainless steel. And you just put that in the little bins and take it for recycling.”

Which means no planks full of nails lying around, waiting to skewer an appendage. So yes, I’m impressed. But I don’t count. What do the experts say?

I speak with Tom Henderson, Clemson University’s building inspector, when he stops by the site to check the foundation on an overcast morning in March. Henderson, under the auspices of South Carolina’s state engineer, reviews the plans and construction details of each campus project that costs less than one million dollars to build, and he’s qualified to inspect every stage of construction. I ask him about his reaction, when he first saw the drawings for Indigo Pine.

A big, sunny smile breaks out across his face. “I thought, wow, I’m excited to be involved in this,” he says.

I ask him if the framing system gave him pause. “I required an engineer’s stamp for the structural part of it, and we got that,” he says. “But there are no weak spots in this system. It’s all built out of plywood, and it fits together like a jigsaw puzzle, like the old mortise-and-tenon or a bunch of Legos. So it’s strong.”

Ty Monks, who owns a structural-engineering company in Montana, has come to town to oversee construction of the prototype. Monks worked with Dan Harding in Bozeman, where Harding was the founding partner of an architecture and design-build firm. I ask Monks for his take on the frame.

“It is stronger than conventional framing, actually, once we looked at some of the testing,” he says. “In compression, it’s about the same as the conventional system, but laterally it’s surprisingly stiff.”

Lateral forces come into play when strong winds, earthquakes, or impacts try to shove the house sideways, shearing or racking its walls. Lateral stiffness is especially useful in earthquake-prone Irvine, California, where the inspectors are expected to give the system their seal of approval.

In fact, the question is not whether the house is strong enough but whether it is too strong. Students working on Indigo Pine became so enthralled with the brawn of their system that for a while they were bulking it up to rival steel-framed buildings and the very rigid joinery known as moment-frame. Harding has advised them to lighten up.

“Though we’re not as strong as steel moment-frame construction, we are much stronger than light wood framing,” he says. “So don’t drive the cost of our system up and overshoot our objective of making it a viable option to replace light wood framing. There’s a saying in Montana: When you go on a hike, as long as there’s at least one person slower than you are, you’re safe from the bears.”

Like Harding’s students, I couldn’t resist, in my youth, the impulse to overbuild. I drove enough nails to construct a small village. On the day the framing inspector arrived, I trailed him around the job site, trying to conceal my anxiety behind a show of tradesman-like detachment. He looked around for a while, signed the green card, and said, “Well, it might rust, but it won’t never fall down.”

The Indigo Pine house, with its stainless steel zip ties, will not rust. And it will never fall down. But to win a contest about energy, the team will have to prove that there’s more to their house than good sinew and bone. How will an all-solar house keep its occupants warm in the winter and cool in the knee-buckling heat of, say, August?

Ways to play it cool

Back in the 1970s, dabblers in solar housing tended to hail from frosty New England, so the few books I found on the topic devoted many more pages to heating than to cooling. I overestimated the need for heat in a heavily insulated, nearly airtight Southern house. Our backup, a Jøtul 118 woodstove, lit only on cold, cloudy days, heaved out so much heat that we opened the windows. We burned about half a cord of firewood a year; the sun did the rest.

But summer’s muggy heat exposed a flaw in my design. I had installed six louvered ports near the living room floor to draw in the cool night air, which rose to push heat through a vent in the roof. This worked as planned, but the Yankee texts I’d read didn’t warn me about Southern-style humidity. By the end of our first summer in the house, the shoes in our closets and the books on our shelves wore a light fur of mildew. Grudgingly, I capitulated and installed a small air conditioner in one of the ports.

Back then, solar panels using photovoltaic cells (PV) were powering some satellites and off-the-grid signaling and lighting systems. But the panels were far too expensive for low-budget dwellings like mine. Today’s PV panels are relatively cheap, cost effective, and efficient, and they have enabled the students to build Indigo Pine as a “net-zero” house, which means it will make as much power as it uses. Employing an efficient new breed of heat pump called a minisplit, the house will put the energy of sunlight to work cooling and dehumidifying the space. That’s something my passive system, for all of its virtues, simply could not do.

Of course the roof space and power available from solar panels are limited, on a house so small. So the Indigo Pine team confronted challenges like those NASA engineers face when they build space vehicles to operate on solar power. Every system has to work lean, earn its keep, and stay cool. Waste and excess heat are not an option.

In the climate of Clemson, South Carolina—or of Irvine, California—that means taking some heat off the house. The less heat invading the interior, the less energy required to keep it cool. Learning from the Carolina farmhouses of long ago, the students designed a porch to provide both extra living space and shade for the western façade. Then they married old with new. After a series of experiments, the team devised a way to use siding fabricated from composite aluminum panels cut and scored on a CNC machine. The supplier couldn’t ship enough white panels in time for the prototype house, so Indigo Pine East wears a sleek, dappled skin of rectangles in charcoal, white, and grey. “It’s like urban camo,” says Will Hinkley, a graduate student in architecture who worked with his classmate Allie Beck on the design.

The panels, secured with rivets, create a cavity between the skin and the sheathing, and the trapped air adds another layer of insulation, Hinkley says. The system deflects so much heat that Harding found a forty-degree drop in interior temperature, after the cladding went up on the prototype. “The difference was staggering,” he says.

But the niftiest heat-reduction system may be the cheapest and simplest of all, and it hides beneath the house. Harding and his students, along with Vincent Blouin, have invented a method for using ordinary concrete blocks—510 of them in the prototype—to create what he calls a “cooler lung,” which the designers tested separately at first but then incorporated into the foundation. At corners and other key structural points, student workers fitted the blocks with rebar and tie-down straps, and filled them with concrete mixed in wheelbarrows. But inside the perimeter, the team laid blocks on their sides, in a staggered checkerboard pattern that directs air through the voids. Water diverted from the plumbing system will drip onto some of the blocks, so that air cooled by evaporation flows to the heat pump.

“It’s like feeding the minisplit Gatorade,” Harding says.

Harding hasn’t collected any data from the system yet, but in theory this low-cost, low-tech lung should take advantage of concrete’s well-known capacity to moderate temperature. “This system could be installed under any mobile home or house with a crawlspace and still decrease the energy use,” he says.

Like most Indigo Pine components, the lung is designed for easy installation. “In every case possible, we like to use unskilled labor, so that homeowners could do it themselves,” Harding says. “We want to get to the point where the money saved can then be applied to more active technologies like solar panels.”

For the competition in Irvine, Clemson’s entry will stand out for its do-it-yourself simplicity. As other schools park heavy equipment on the site, the Indigo Pine team will make do with the kind of gear a family could tow home from their local rental yard. Eric Balogh recalls meeting the competition, when contestants gathered in Irvine earlier this year to learn the ground rules. “The team next to us approached us and asked if we wanted to share a crane,” Balogh says. “We said, ‘Nah, we’re okay. Thank you, though.’”

Behind the house, another sort of building

This kind of do-it-yourself simplicity is Exhibit A in Indigo Pine’s claim to sustainability, because it could, in theory, help make solar housing affordable for families almost anywhere. In architecture, the concept of sustainability is fluid and sometimes fervently debated, but generally it means creating buildings and communities that are, for the long term, socially, economically, and environmentally sound. Homeowners or nonprofit groups such as Habitat for Humanity could build a version of the Indigo Pine house and do most of the work with unskilled labor, team members say. Locally sourced plywood makes efficient use of forest resources, and the house’s solar-powered systems and energy efficiency would earn it high marks on the environmental scale.

Attributes like these will tend to make the building sustainable. But to understand what makes a project like this one sustainable we’ll have to step back from the house.

Indigo Pine’s backstory has many chapters, and I cannot do it justice in these pages, any more than I can document the thousands of calculations, choices, and leaps of imagination a team of architects and engineers will make en route to a finished design. But I did find a man who could run through the gist.

One evening last March, as freezing rain and sleet began icing the roads, Vincent Blouin sat in his office until long after dark and patiently answered my questions about the evolution of Indigo Pine. For two years, Blouin has been the project’s principal investigator and administrative lightning rod. He did not build the house, but he, along with Dan Harding and their colleagues, built the capacity to build the house. That means they wrote the grants, wrangled the money, planned the curriculum, rounded up the corporate partners, cultivated the donors, navigated the federal bureaucracy, and assembled the framework of expertise and administrative wherewithal necessary to enable their students to enter a national competition and delve into something dramatically, daringly new.

For an endeavor this ambitious, it helps to tap the resources of an architecture school with plenty of green-building expertise on hand. Let’s pick two examples, among many: Ulrike Heine, an expert on sustainable design, has supplied Indigo Pine with advice and resources, and her students arrived on the project already versed in the principles of net-zero housing; Dustin Albright, who studies the efficient use of wood products such as cross-laminated timber, influenced Indigo Pine’s plywood-based structural system and brought his construction know-how to the team. For Blouin, who has a joint appointment in architecture and in engineering, the decathlon was a way to muster this kind of expertise from multiple colleges at Clemson, to step up the science of green building in a visible way.

“Our participation in the Solar Decathlon has the potential to significantly advance the standards of design and construction of market-rate, affordable, zero-energy housing for families in South Carolina and beyond,” Blouin says. “We have designed a small Southern home that lives big.”

From an academic perspective, sustainability also meant launching a project that would generate useful research, and Indigo Pine has aced that test. Dan Harding can recite a long list of research questions raised by the project, which will yield data on energy production and use, air temperature, passive cooling, construction and workforce economics, and more. The house, he says, is a laboratory. “Just researching the foundation system will be a project with incredible offshoots.”

The lab-like nature of the effort became clear one afternoon in March, when I pulled up a chair for one of the Indigo Pine team’s weekly briefings in Harding’s studio on the ground floor of Lee Hall. As the briefing progressed, I couldn’t help but suspect that Harding had brought in a room full of ringers. These were not a bunch of novices muddling through a half-baked class assignment. The students spoke like pros—succinct, business-like, and fluent. In less than an hour, more than a dozen presenters described, in detail, each major aspect of their project.

Alison Martin walked us through the protocols of job-site safety. Jeff Hamrick and Eric Balogh summarized the voluminous documentation they’d submitted to the DoE and gave status reports on structure, architecture, fire protection, mechanical and electrical systems, interiors, landscape, and operations. Will Hinkley and Allie Beck outlined changes to the porch and a series of experiments that refined the cladding to neatly align with the windows and doors. Justin Hamrick and Jon Pennington reported on structural testing. Clair Dias covered logistics and laid out a calendar of milestones and events, including a ribbon cutting in April with President Clements.

As I listened to these students and others in their cohort, I could hear in their updates a pattern of values and themes. They were telling a story about the future of housing, and the possibilities of architecture—a kind of motivating mythology that had been feeding the project for two years. The story was reaching its climax, a convergence of effort by many students. Some of them had graduated, handed off their concepts and models, and moved on. Over time, the faces at the table had changed. The models and materials had changed. And the school itself had changed, because Indigo Pine was rapacious. As it grew and found its bearings, it stalked every corridor of Lee Hall, gobbling up whatever knowledge and talent it could corner. And now the students who’d inherited this monster were determined to make the mythology real, to give it flesh and let it stand for what they’d learned.

“The project has exposed students and faculty alike to a whole new level of architecture education,” Dias says. “It’s left its footprints all over Lee Hall.”

Architecture students weren’t the only ones feeding the beast. When I first arrived on the site of Indigo Pine East, on day one of construction, I found Edward Hoegg, a graduate student in chemistry, wiring breakers and outlets for the temporary power supply. A volunteer, Hoegg had steeped himself in the technology of solar energy during a three-year stint with the DoE’s SunShot initiative, and he’d learned electrical work as a lighting and sound engineer for concerts and events.

Like Hoegg, Michael Stoner, a civil engineering student, supplied some much-needed technical expertise. Stoner first learned about Indigo Pine at Clemson’s villa in Genoa, Italy, taking a summer-session course with Dan Harding and Clair Dias. He came back from Genoa ready to help on the project, signed on to conduct some research with Dustin Albright, and used his skills to test components of its structure in the engineering lab.

Over the course of two years, the contributions of many people, from multiple schools and departments, began to cohere. Students were learning the habits of rigor, inquiry, and creative collaboration that would shape their careers. And that, for a university, may be the ultimate measure of sustainable design.

Beyond the black hole

Anyone who has built a house from scratch has faced that moment when the project becomes a black hole into which money and time disappear. I became acquainted with the abyss sometime around Christmas of my second year of construction, when I was running out of money and working late at night in bitter cold. By the light of a sixty-watt bulb, in a powdery cloud of white dust, I was sanding down thick, spiny crusts of hardened joint compound I had over-applied to the drywall. The errors of inexperience are costly but instructive.

At last count, the budget for Indigo Pine was faring better than mine did. Donors and corporate sponsors have been generous, contributing most of the materials and equipment. But as the semester wound down through late April into May, construction did not always proceed according to plan, and the prototype fell behind schedule. Sometimes, materials or equipment failed to show up on cue. Now and then, a gremlin popped out of the woodwork. Leveling the floor joists, for instance, was fiendishly tricky and cost a whole day.

“Also we had a learning moment with the box girder,” Dias recalls. “It’s about twelve hundred pounds, and getting it into place was something we hadn’t thought through. We finally figured out a safe and effective way to install it. We removed a couple of bolts.”

Now, on this hot day in May, as I poke around on the site, Eric Balogh calls down from the rafters, asking for a two-by-six joist for the porch roof he’s building. The news isn’t good. “We’re out of those,” someone hollers. The best remaining two-by-sixes are wet with freshly painted stain; the only dry one is as crooked as a dog’s hind leg. So Balogh climbs down for a water break. “We’ve had lots of schedule revision,” he says with a shrug, when I ask him about the delays. “We actually had to stop for two weeks so that everyone could pass their finals. Now it’s nice because no one’s stressed out about classes and finals, and it’s just six of us here for now. We should have ten for the summer, when everyone gets back from vacation.”

Balogh doesn’t sweat the setbacks. This is why you build a prototype, he says—to work out the kinks before the competition. He’s optimistic that assembly will keep pace with the schedule when the team convenes in California. “Every time we try something new we learn what went right and what went wrong,” he says. “I think the biggest lesson we’ve learned is to spend more time planning and less time actually building. It needs to be more about assembling the house, not building it.”

During the nine days of building in Irvine, the team will use two crews of twelve people each, running two eight-hour shifts a day. Balogh will manage one crew and the aptly named Jeff Hammer, a fellow graduate student in architecture, will manage the other.

Unlike most of his classmates, Balogh has a background in construction. He worked for a design-build firm in Augusta, Georgia, for several years before he came to graduate school, and he spent some time on job sites. When he arrived at Clemson, he had his doubts when he first saw the structural system under development in the Lee Hall studio. “I won’t lie,” he says. “I was a bit skeptical, at first. But it has actually been incredibly smooth, very safe, and very quick. It was this big theory, this big idea, and it’s working.”

When I catch up with Dan Harding, later that day, he’s been packing for another summer in Genoa. “I’ll stay in contact with the project,” he says, “but this is the end of our third academic studio on the project. The next semester is doing it. So at this stage, the creative thinking has to be on the team’s shoulders, or the ownership doesn’t get transferred.”

The team will manage fine without him, he says. “The crew that’s here right now is as proficient as any group I’ve ever worked with. If I could take everyone in this studio, I’d start an office, and I know that we would win. There’s no doubt.”

Harding can’t promise a win in California, but the team will be ready, he says. And whatever the outcome of the competition, the students have already achieved more than they’d imagined. Many will emerge from the project transformed. Michael Stoner came to the mix an engineer wary of artsy design types. But after his time sketching buildings in Genoa, and his collaboration with student architects on Indigo Pine, he has a different view of the relationships of architects and engineers.

“My focus as an engineer is different, now,” Stoner says. “I’ve learned to consider how an architect can make something beautiful, if I can help by engineering something that may not be conventional.”

Several students have told me about similar transformations. Building a house from the ground up, they say, has changed the way they see the structure. It’s not just a concept in pixels or ink, anymore.

Here’s how Eric Balogh puts it: “You can draw and draft and look up details to your heart’s content, but until you really understand that the pencil-thin line you just drew is actually a thick piece of metal or rebar or something, it really doesn’t click. It’s kind of that click, you know, and it’s incredibly important.”

That rings true, for me. Most of what I’ve produced in the last thirty-eight years, including this magazine, I composed within the mental framework, the analogue, of designing and building a house. In some ways, I still dwell there, even though I sold the place and moved to town. But I had forgotten, until I spent a little time with the students on Indigo Pine, that building a solar house is not something you do only for shelter, or bragging rights, or even the credential. You do it to stake your claim to the future instead of the past.

The students headed for Irvine won’t have to go it alone. They will have teammates and coaches. They will have the backing of their university, their donors, their industry partners, and their government. They will go armed with some impressive new technology and the know-how to use it. If they win a prize, good for them. But what I’m really counting on is something more: Help us find our way back to the sun.

Vincent Blouin is the principal investigator for the Clemson Solar Decathlon project and an associate professor of architecture and materials science and engineering, in the College of Architecture, Arts, and Humanities and in the College of Engineering and Science.

Dan Harding is an associate professor of architecture and director of the Community Research & Design Center. Ulrike Heine is an associate professor and associate chair of architecture, and Dustin Albright is an assistant professor of architecture. All three are in the College of Architecture, Arts, and Humanities.

The project is funded in part by the Office of Energy Efficiency and Renewable Energy (EERE), U.S. Department of Energy, under Award Number DE-.EE0006559. For more about Indigo Pine, including sponsors and participants, go to www.clemson.edu/indigopine/.

Neil Caudle, editor of Glimpse, now lives in an active-solar house that he did not build himself.