Bringing industry to light

by R. R. McCarthy

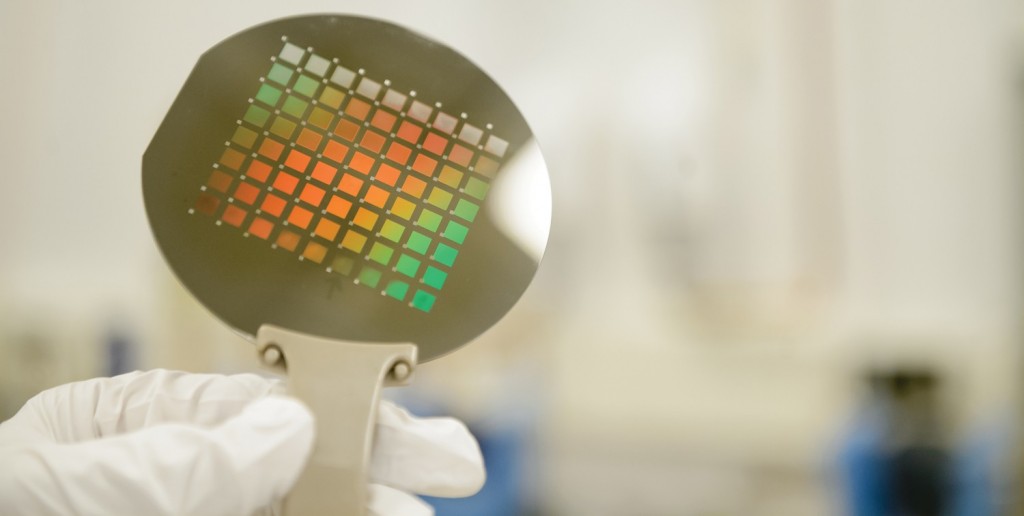

Wafers like this are part of research that could revolutionize how computers work. Here, a chrome-coated glass substrate holds multiple patterned devices. Photo by Ashley Jones.

Wafers like this are part of research that could revolutionize how computers work. Here, a chrome-coated glass substrate holds multiple patterned devices. Photo by Ashley Jones.

In a Clemson laboratory, students play with light.

They test blue lasers designed to beam data under water. Atom by atom, they sculpt complex patterns in wafers of silica and sapphire that can control, detect, and manipulate light. And it’s all part of Eric Johnson’s plan to put U.S. industry on top.

Since he arrived at Clemson four years ago from the University of North Carolina at Charlotte, he has become something of an optics and photonics rock star. But Johnson is down to earth and self-effacing. He’s comfortable talking both with colleagues and elected officials. He easily collaborates with scientists from other departments about the ways that lasers may have applications for their work, such as automotive innovations. He is comfortable discussing research topics with private industry representatives or recruiting students. With everyone, he conveys the same excitement about what his lab does and what it can eventually do for South Carolina.

“I can’t say enough good things about Eric as a professor,” says Clemson graduate Aaron Pung, who earned a Ph.D. with Johnson in 2014. Pung now works on classified projects at Sandia National Laboratories in Albuquerque, New Mexico. “He’s smart and he always has another card up his sleeve. He has so many ideas, the amount of time and effort he puts in for students amazes me.”

Johnson’s field, optoelectronics, is the scientific study of electronic devices that produce, detect, and manipulate light. It’s a field that has helped create technologies used in national defense, medicine, communications, manufacturing, and in a wide variety of other fields.

His résumé includes past positions directing research and development departments in private industry, where, for example, he helped develop bar code scanners and the technology that enables computers to communicate with each other. His research in micro-optics and nanophotonics has resulted in thirteen patents. He also has had a stint as a program director in the Electrical, Communications, and Cyber Systems (ECCS) Division of the National Science Foundation, where he managed research funding for photonics programs around the country. And he has had faculty positions at other universities in North Carolina and central Florida with flourishing optics programs.

His two-year appointment in Washington gave Johnson a good picture of the state of photonics and optoelectronics in the entire country. Photonics, the scientific study of light and light technology, underpins everything from tools for eye surgery to remote sensing and weapon systems, cell phones, and the Internet. During his time there, Johnson had one of his early suspicions confirmed: A big weakness in national planning here in the United States is a lack of emphasis across the country on photonic manufacturing.

Few companies in the United States can bring such technology to market. Often aided by governments, companies in Asia and Europe long ago invested in the infrastructure needed for such manufacturing. It’s no surprise, then, that smart phones aren’t made here. The cameras in cell phones use both glass and silicon chips that interface and work together—and it’s done inexpensively.

“All of that is done overseas now, not in the U.S. at all,” Johnson says. “Putting optics and photonics together in computers, that’s a problem that Intel is trying to solve, heterogeneous integration. Those high-volume applications have the real payoff.”

A clean room at the Advanced Materials Research Laboratory gives Clemson researchers and students access to microtechnologies. Photo by Ashley Jones.

A clean room at the Advanced Materials Research Laboratory gives Clemson researchers and students access to microtechnologies. Photo by Ashley Jones.Closing a high-tech manufacturing gap

Without the infrastructure of a manufacturing industry, the U.S. won’t be able to compete globally, according to Johnson, no matter how many technological breakthroughs there are. Many of the international students who complete advanced engineering degrees at Clemson and other American universities are going to return to their home countries, where jobs are more plentiful.

“The lack of manufacturing stifles development,” he says. “All the chip manufacturing is going to Europe and Asia. But I do think we’re going to work on closing the gap.”

With its investments in faculty, equipment, and facilities—including a clean room, a chamber with no detectable dust or other contaminants, which opened last fall—Clemson University is poised to play a part in changing the manufacturing landscape for photonic devices, Johnson says. In the university’s labs at the Center for Optical Materials Science and Engineering Technologies, researchers can make customized optic fiber as well as photonic chips.

“We’ve taken the first step of getting our facilities up and running, and now we’re expanding,” Johnson says. “Having the clean room will make a big difference. More importantly, the capabilities are critical to all the microtechnologies out there. Students need to be able to learn how these things are done.”

By students, Johnson means high schoolers as well as undergraduate and graduate students. This summer he is using his internal funds to support a local high school student, as he has done in the past with a student from the South Carolina Governor’s School for Science and Math, which is part of the SmartState system. The teenager will work alongside graduate students on a project for two months, producing a poster and possibly a peer-reviewed published paper.

“I want bright students to consider studying engineering,” he says. “So many kids don’t even think about it, it’s a kind of brain drain. They learn they can do really cool stuff with optics.”

A tiny window to the possible

Take a little thing made by graduate student Indumathi Raghu Srimathi. Her amazing creation is about the size of a fish scale, as clear as a tiny windowpane. When you look at it under a microscope, you could be looking at a 3-D slide of the Grand Canyon’s topography. But when you shine a red laser pointer on it, an orange Clemson Tiger paw appears. It looks so simple, but a lot of work went into making it.

Essentially, what Srimathi did, says Johnson, was to mimic a phenomenon found in nature. A butterfly’s wings have no color—what you see is diffracted light. What you see in the tiger paw, too, is diffracted light. Srimathi started with a fused silica wafer, a pure form of glass. She used atomic layer deposition to add different materials, atom by atom, to the wafer. She then coated it with photoresist, exposed it to ultraviolet light with a photolithography tool, and washed away the chemicals. Hit it with a laser point and voilà, a tiger paw.

Knowledge jobs

Eric Johnson is one of fifty-one professors in the state who receive funding from SmartState, a South Carolina program that combines public and private money for research professor endowments. The South Carolina General Assembly created the SmartState Program in 2002, thinking that the best way to improve South Carolina and its economy would be to give its citizens better jobs, knowledge-based jobs.

To do that, legislators asked the state’s three public research schools—Clemson, the University of South Carolina, and the Medical University of South Carolina—to create centers of economic excellence. Today, there are fifty-one centers that focus on topics such as advanced materials and nanotechnology, automotive and transportation, biomedical, energy and alternative fuels, information science, and pharmaceutical advances.

The SmartState Program also includes funding for SmartState Endowed Chairs, like the one held by Eric Johnson, that are also funded by private industry. For Clemson, sixteen endowed SmartState Endowed Chairs have been created, and six of them appointed. Like Johnson, the professors holding the chaired professorships are accomplished engineers and scientists. Their research and innovations are powering the economic excellence centers.

In the past 13 years, the State of South Carolina has channeled $197.6 million in state lottery monies into the SmartState program, and private industry has contributed additional money. The program has been credited with creating more than 10,000 jobs, 4,880 of them knowledge-economy jobs. Studies show that knowledge-based jobs on average pay $78,393 and lead to the creation of other jobs. According to the South Carolina Commission on Higher Education, the entire program has an annual economic impact of $1.5 billion.

Diffraction is an alteration that light undergoes when it passes along the edges of opaque bodies or through narrow slits or, as in the present case, is reflected from irregular surfaces. The result is the production of a potentially infinite number of patterns, each specific to a particular reflecting surface, of which Srimathi’s tiny chip is one. Diffraction occurs not only with light but also with anything composed of waves—sound, X-rays, water waves, and so forth.

Diffractive optics has many applications for the private sector—there are companies using it to make just about any logo. Virtual keyboards also make use of diffractive optics and laser technologies. So does remote sensing and industrial machining.

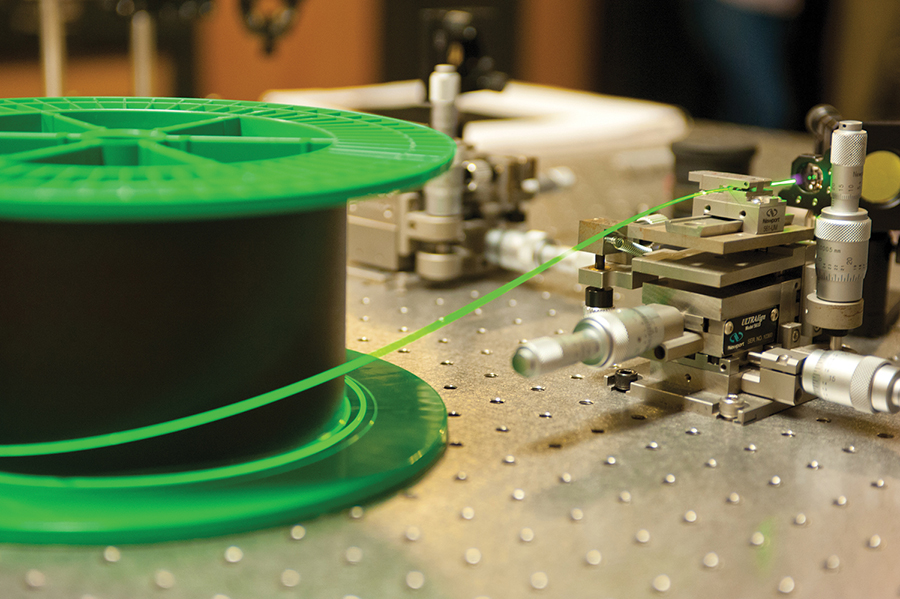

Other students in Johnson’s lab are doing research on blue laser wavelength control devices, funded by the U.S. Navy. The navy is interested because, when applied to telecommunications, blue laser control devices are a vast improvement over traditional forms of underwater communication, such as radio frequency waves and acoustic systems, which are easily jammed and easy to detect.

Research and testing have demonstrated the advantages of blue laser devices, which include a higher data rate, increased security, and the potential for multiple channel encoding. Multiple channel encoding means that information can be split among different components, which can be transmitted along the same channel at the same time.

Blue lasers have a shorter wavelength than the traditional red laser used in most electronic applications today. They emit electromagnetic radiation with a wavelength between 360 and 480 nanometers (nm), which the human eye sees as blue or violet. Red lasers emit in the 600–700 nm range. Because the wavelength is shorter, blue lasers allow data to be more densely packed. The result is that storage devices—say, a compact disc—of the same size are able to store two to four times as much information with blue laser technology than they did with red.

The principal student investigator on the project, undergraduate Matthew Byrd, is headed to MIT this fall on a National Science Foundation Fellowship. There, he expects to be exploring silicon photonics, the study of photonic systems that use the element silicon as an optical medium. He plans to work with a professor who’s trying to develop silicon chips that have discrete components on them, including a lens, laser diodes, and a control device. It’s a toolbox that will be integrated to work together so that it will be possible for the chip to be mass produced, Byrd says.

Lumany, a company in Newport Beach, California, is taking research developed in Johnson’s lab and transferring it to the marketplace, says Lumany CEO Paul Rudy. He has known Johnson and his work for fifteen years. Lumany, Rudy says, makes “innovative lasers to replace conventional lasers.”

He says Johnson understands how to leverage the resources of an academic institution like Clemson to develop research into commercially relevant technology, in this case, high-powered lasers that are of potential interest for the U.S. Navy. The company is using a multi-phase Small Business Technology Transfer (STTR) grant of about $1 million on the project, which aims to develop lasers that can be more precisely controlled.

“Eric and his team have always delivered, they’ve always come through with innovative results, which is hard to do,” Rudy says. “In fact, it’s remarkable.”

Research in Eric Johnson’s lab develops the potential of lasers and optical fiber in manufacturing. This mid-infrared fiber laser shows green fluorescence under strong optical pumping. Photo by Craig Mahaffey.

Research in Eric Johnson’s lab develops the potential of lasers and optical fiber in manufacturing. This mid-infrared fiber laser shows green fluorescence under strong optical pumping. Photo by Craig Mahaffey.

Eric Johnson holds the PalmettoNet Endowed Chair in Optoelectronics. He also serves as the head of the South Carolina SmartState Center of Economic Excellence in Optoelectronics. R. R. McCarthy is a freelance writer based in Athens, Georgia.