a drop of water, a speck of coal

Neil Caudle

Steven Fredericks thumbs the plunger of a syringe, expels a few squirts to clear air from the tip of the needle, and lowers the needle toward a polished metal disk. When a new drop appears at the tip of the needle, an invisible force seems to seize it and float it in air.

Fredericks sets the syringe aside and twists a knob on an amplifier nearby.

We hear nothing from the hardware, but the drop begins to vibrate, dancing.

It leaps and darts, jolted from side to side. As Fredericks fine-tunes the voltage, the dancing calms, the drop aquiver, as though from its frantic exertion.

Fredericks, who helped assemble the equipment, is a master’s student working in the lab of John R. Saylor, a professor in the Department of Mechanical Engineering. Fredericks has just demonstrated how to levitate a drop. He does it with unheard sound.

The force that lifts and holds the drop is inaudible to humans but would madden a dog. It is an ultrasonic standing wave field—one wave emitted and another reflected, matched in their coming and going so that in their symmetrical embrace the drop is trapped and held in place, pulsing like a heartbeat.

It’s a clever trick that savvy magicians might try on the stage. But drop levitation, a technique developed in part by Saylor’s collaborator at Boston University, R. Glynn Holt, has more to offer than sleight of hand.

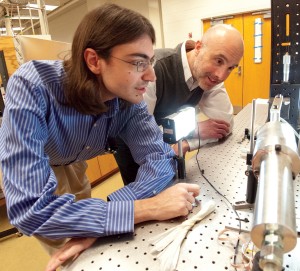

Steven Fredericks (left) works with John Saylor (right) to fine-tune a device they built to levitate droplets and help them study the effects of various frequencies of ultrasonic sound. Photo by Craig Mahaffey.

Where it’s dark as a dungeon

Hold in one part of your mind the gentle levitation of one silvery drop and in another its opposite: a vast, craggy underworld where enormous machines with burr-like cutters gnaw the bones of a mountain, shearing coal from the walls of a mine gallery, crushing the coal into chunks and great billowing clouds of black dust. People are working here, sometimes a mile below daylight. A ventilation system forces fresh air down a duct to them, exhausting a stale, dusty flow. And spray heads drench the workspace with water to settle the dust. But airflows and sprays do not capture all of the floating coal dust particles. Nor do they capture all of the particles from the exhaust of diesel engines that power the mining machines. These particulate contaminants flow into the coal miners’ lungs.

Saylor is not an epidemiologist, but he devotes careful attention to coal miners’ lungs. He says our bodies can trap and expel most of the largest particles from coal dust and diesel exhaust. But particles having a size on the order of a micrometer in diameter elude our defenses. Cigarette smoke, coal dust, and diesel exhaust all carry a heavy load of particles in this size range. “When you take a massive cutter and use it to grind coal into pieces that can be moved to the surface, you’re going to create particles of all sizes,” Saylor says. “Particles in this especially hazardous size range can navigate the twists and turns of our nasal passages, reach the most distal recesses of the lungs, and stay there. And that’s what causes black lung disease.”

According to the National Institute for Occupational Safety and Health (NIOSH), 1003 miners died from coal workers’ pneumoconiosis—black lung disease—in 1999 alone. From 1995 to 1999, 26.2 percent of recorded exposures to coal dust exceeded recommended levels. And some 30,000 miners in the U.S. are exposed to unsafe levels of particulates from diesel exhaust, a carcinogen. The main defense against these deadly threats? Tiny drops of water.

Large drops have been levitated at nodes of the ultrasonic standing wave field. These drops are formed from the accumulation of many fine water drops, introduced from the left. The large drops continue to grow until they become too heavy to be supported by the ultrasonic standing wave field.

Bubbles and drops

Saylor has long had an interest in bubbles and drops, and a spray, he says, is nothing but a lot of drops. He also studies what he calls the nexus of water and energy, the inescapable fact that producing energy with conventional fuels requires vast amounts of fresh water.

Coal mining is a case in point. If Saylor and his students can devise a way to make sprays more efficient in coal mines, they may help save water and lives.

Which brings us back to the levitated drop.

What if you could, with an ultrasonic standing wave, levitate not just one drop of water but millions, suspending them long enough to intercept most of the dangerous particles from coal dust and diesel exhaust?

What if the drops and particles began crowding together so tight that their accumulating weight would sink them safely to a drain?

This is exactly what Saylor and his students have done in his lab. Using their drop-levitation technique, they have created what Saylor calls an accretion disk, where drops and particles collect.

As Fredericks works drop by drop, Weiyu Ran, one of Saylor’s Ph.D. students, works with many drops—with sprays.

Saylor and Ran have designed and constructed a small-scale scrubber, a device that forces sprays and a flow of particle-laden air to combine in an enclosed chamber. By creating accretion disks inside this chamber using ultrasonic energy, far more particles are removed from the air than would otherwise be the case.

Weiyu Ran, a Ph.D. student, worked with Saylor to design and construct a scrubber, a device that forces sprays and particle-laden air together in a chamber.

Scaling it up

So at least in the lab, the method works. But what about in coal mines?

Saylor is looking for ways to scale up the technology for testing in mine-like conditions. Mining operations would probably balk at the electricity required to power a very large wave field, because errant voltage in a dusty mine might spark an explosion. So an ultrasonic standing wave field may not be practical for treating whole underground rooms. There is also the problem of the volumetric flow rate of air, which is enormous in mines compared to values employed in the lab. “The first step may be to use our device in a smaller compartment,” Saylor says, “like the cab of a mining vehicle, or in a scrubber like those used to reduce air pollution from smokestacks.” Getting to that stage will require cooperation from industry and government, and Saylor is starting with NIOSH’s Office of Mine Safety and Health Research in Pittsburgh. Meanwhile, he and Ran are preparing to publish their data from the small-scale ultrasonic scrubber. While the results so far are encouraging, Saylor knows that scaling up will mean taking the science to another level, analyzing in detail the complex interaction of particulates and drops in wave fields of various sizes. This will take some time, and the clock is ticking for people who work in the mines. “Black lung disease has been increasing, not decreasing,” Saylor says. “What would be very satisfying to me would be saving lives.”

John R. Saylor is a professor of mechanical engineering in the College of Engineering and Science. Photos by Craig Mahaffey.