a pipe full of star power

by Neil Caudle

Five years ago, Chad Sosolik came back from Washington with a crazy idea. Look what followed him home.

If you had a star, you could strip a great storm of electrons away from its atoms and make all of the highly charged ions you might need. But you couldn’t hang around to watch. Or you could do what Chad Sosolik has done: You could harness a rare and remarkable beast known as an electron beam ion trap, an EBIT, one of only six in the nation, and the only one not housed in a national laboratory or institute. You could use that million-dollar marvel of high-tech plumbing to simulate stellar forces on an Earth-bound, observable scale. You could trap a cloud of highly charged ions and shoot them at targets. You could use the beams to irradiate, say, oxides or carbons or plastics.

And that’s what Sosolik and his colleagues and students are doing, at the moment: blasting various materials with very highly charged ions. “We’re experimenting with things that never have touched, at least on Earth, these ions before,” he says.

Sosolik is a lean, rangy Texan, the kind of guy who might well indulge a bit of boyish delight in blowing stuff up. But destruction, in this case, is only a means to an end. He has a hunch that a new generation of advanced materials, patterned by highly charged ions, awaits discovery by those with the right kind of tools. And that’s what Sosolik has installed in the basement of the Kinard Laboratory of Physics: the right kind of tool.

If his hunch is correct, a great deal of knowledge and technology will flow from his futuristic pipework. Sosolik can imagine, for example, materials that could eventually become semiconductors or capacitors or high-precision filters. And the EBIT, he believes, will give Clemson, already a player in the high-stakes game of advanced materials, a significant home-field advantage.

But why Clemson? How did this coveted tool of plasma physics wind up here, and not in some powerhouse lab in the research elite? The answer, in short, is that Sosolik was in the right place at the right time, and he knew how to ask.

And it all started with an overheated lab.

Looking for cool

About seven years ago, Sosolik’s lab building was due for an overhaul of its air-conditioning system, and he and his graduate student faced the prospect of baking themselves in an oven all summer. Sosolik, looking for a more temperate spot for his student to work, called on a colleague he’d known since graduate school, Joshua Pomeroy, who’d wound up as a staff scientist at the National Institute of Standards, NIST, in Gaithersburg, Maryland.

“In the lab where he works, he has the second EBIT built in the U.S.,” Sosolik says. “It’s an older machine, from the early nineties.”

With the summer heat arriving, Sosolik swung a deal with his friend at NIST. “My student went up there to work in an air-conditioned lab and never came back,” Sosolik says, laughing. “He got a Ph.D. from Clemson, but all of the research was done there, at NIST, with their EBIT. So because of that student I got very involved in this kind of research.”

So EBITs were on Sosolik’s mind one day in the summer of 2009 when he happened to be sitting on a review panel at the National Science Foundation (NSF), just as Washington was ramping up the economic-stimulus program known as the American Recovery and Reinvestment Act.

“The NSF program manager walks in and says, ‘We just found out we’re going to make a special call for big equipment proposals, and if you guys have any good ideas, you’re the first ones to know,’” Sosolik recalls. “And then, typical of NSF, he says, ‘You guys have thirty minutes for lunch. Go.’ So I just walked next door into a mall that’s connected to NSF and sat down in a fast-food joint and got on my phone and called this guy at NIST and said, ‘What do you think? Maybe we could buy a spectrometer or something?’ And he’s like, ‘Get your own EBIT.’ And I said, ‘You’re insane.’”

Insane or not, they kept talking, and Sosolik began to warm to the idea. Trouble was, even at the NSF, an EBIT was a rarified exotic that few understood. He would have to sell the idea, and fast, to get a jump on the competition.

“I made a few calls, changed my flight, and stayed at NSF for an extra day,” Sosolik says. “I walked from office to office, and I told people what an EBIT was, and that I was going to put a proposal in for one, just to explain it to them, just so they’d know it was coming. Then I came back to campus and wrote a proposal, and we formed a team.”

In the normal course of research funding, an NSF project on this scale requires a substantial match from the institution—a staggering hit for the budget at Clemson. But in this case, the feds had decided to give some less-affluent schools a fighting chance. “They sent out a list of ‘research-one’ universities, and if you didn’t cross a certain threshold in terms of per-capita funding at your university, there was no required match,” Sosolik says. “So I went down that list very closely, and I kept going and going, and finally I got to the line, and I thought, ‘We’re not on it.’ It was that rarest of rare equipment grants. We didn’t have to come up with a match.”

Clemson won the award; the request was fully funded. It was time to go shopping.

“I have a million. What can I buy?”

Sosolik had long aspired to buy an EBIT from a group at Lawrence Livermore Lab, where the first EBIT in the United States was built. “But when I called the guys at Livermore they said, ‘We don’t make it anymore.’ They’d had some technical difficulties. One of their EBITs sits at Harvard right now, and it’s turned off. There was one in Stockholm as well.”

His friend at NIST had told him that a group in Germany could build a turnkey EBIT with all the modern bells and whistles. “So I got on the phone to Germany,” Sosolik says, “and said, ‘I have this million-plus dollars. What can I buy?’ I think they were stunned.”

Improbably, Clemson had leaped to the head of the line for this newest and coolest of EBIT machines. “We would be the only institution in the United States that would be set up to do this kind of radiation on materials,” Sosolik says. “There are other EBITs, but they’re older, and they cost more, and they’re not set up to do targeted research in materials, which is a strength here at Clemson.”

So a crew in Dresden went to work building the new machine. It was almost finished when an electron beam went astray during testing and cut through some welds at the back of the machine. “They de-welded it, basically,” Sosolik says.

To make up for the resulting nine-month delay, the Dresden team threw in an extra feature Sosolik had coveted but hadn’t thought he could afford: a special fitting that would let him access the beam line and trap from a different angle. The machine arrived at last and, after a period of installation and testing, went online in April of 2013. By pure accident, I’m visiting the lab on the EBIT’s one-year anniversary. I ask Sosolik if he’s planning to celebrate, thinking there might be cake.

“Well, I’m running a half marathon tomorrow,” he says.

Look but don’t touch

So I’m wondering, as I sit behind a computerized control panel peering through glass at a room full of futuristic hardware, hearing it chitter like some great hive of alien arthropods, just how safe we are, given that the EBIT’s beam has already proven itself more than potent enough to melt welded steel.

“Do you have a pacemaker?” Sosolik asks.

“No,” I say. “Not yet.”

“Well, you should be fine.”

Should be. That’s encouraging. The EBIT uses a superconducting magnet operating at six tesla—hence the caution about pacemakers.

We cover a few more of the risky forces inherent in this kind of physics. For example, there’s a portal through which researchers will observe the ion cloud by capturing images of the patterns of X-rays it emits. The portal is X-ray transparent, but I shouldn’t worry about getting irradiated, Sosolik says. The machine isn’t running today, and besides, the portal can be closed or blocked with whatever device is attached to it. And the high-voltage electrodes, each carrying tens of thousands of volts? They are protected by insulators, smaller versions of the kind we see on power poles. The electrodes are also sealed, so I can’t accidentally stick my fingers in there.

All of this high-powered hardware generates tremendous heat, the enemy of metal and magnets. The EBIT uses four separate cooling systems, including three for circulating purified water and one for cycling helium in and out of the superconducting magnet at 4 kelvin, which is very, very cold. To dump heat from the circulating water, the team hooked up a heat exchanger connected to the main campus chilled-water system. In effect, the EBIT keeps its cool while the campus takes the heat. But there’s plenty of cooling capacity to handle the load, Sosolik says.

All of this cooling depends on reliable power, so the backup generator gets considerable attention and is still being tweaked. If the power should happen to go out, the system will automatically contact both Sosolik and his partner in the lab, Jim Harriss, so they can hustle back to the lab and shut things down in an orderly fashion while the backup generator keeps the cooling system running.

Turning the corner

Its safeguards having been tested and proven, the EBIT is working according to plan. But the power of this thing is otherworldly. And it all begins, innocently enough, with a modest little cathode and a teeny, tiny hole.

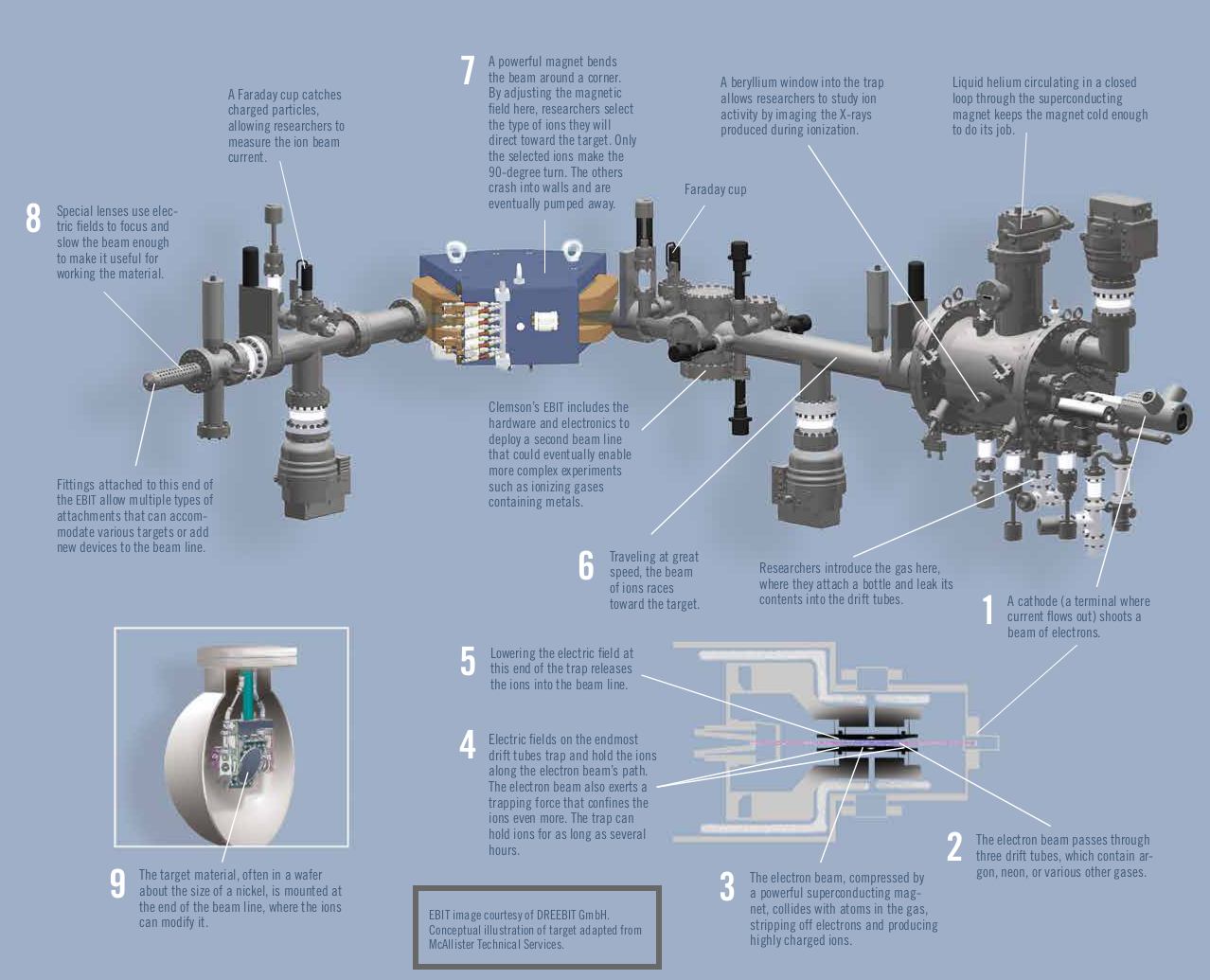

Harriss, who has been putting the EBIT through its paces and teaching people how to use it, explains what happens, at the most basic level, when the EBIT is running. At the front end of the EBIT, the cathode fires a beam of electrons through an opening five millimeters in diameter. The electron beam proceeds through a chamber full of gas, and the beam knocks electrons off the atoms in the gas, creating ions. Electric fields at each end of the chamber trap the charged particles.

“The electron flow itself will attract the ions, and concentrate them toward the center of the trap,” Harriss explains. “But also, wrapped around all of this, is a very strong magnetic field, which also helps trap the ions.” The magnetic field, he says, compresses and concentrates the electron beam to make it more efficient.

After the beam has knocked enough electrons off their atoms, the researchers lower the voltage at the end of the trap, releasing a pulse of ions downstream toward a left-hand turn. Forcing ions around a corner is sort of like herding cats, but that’s how the researchers select the kind of ions they want from the beam. As various ions race down the line carrying various charges, the researchers apply a powerful magnetic field to bend them off course. Only the selected ones bend at ninety degrees, turn the corner, and head for the target.

All of that is much easier said than done.

“In order for us to get ions from there”—Sosolik points to the segment where the trap is housed—“around the corner, without the beam just blowing up, we have to transport at high velocity, which means high energy. The whole thing gets floated up at several thousand volts, which effectively tricks the ions into thinking they can travel faster if they go around the corner. So we get them around the corner fast and then there’s a lot of special optics at the end to slow them down, get them focused, and direct them to the target.”

The optics includes special lenses made of electrical fields, not glass, but they work much the same way as lenses for focusing light. “The math’s exactly the same,” Sosolik says. “If you work out the math for a classic ion-electron lens, and make your formulations for optics, you get exactly the same optics as light optics. You can get a concave lens, you can get a convex lens—you can do all the same stuff.”

And to change the focal properties for an ion-electron lens, the team does not have to replace the lens or regrind some glass. They just dial up a new set of voltages.

By slowing the flow with optics, Sosolik says, the ion beam has time to work its magic on the target material. “If you don’t slow it down, you’re not letting the physics play out on the target,” Sosolik says.

The iron in the wind

So far, Sosolik and his team are making ions from elements called noble gases, a group that includes helium, neon, argon, krypton, xenon, and radioactive radon. Noble gases are odorless and colorless, they have similar properties, and they can be used to make highly charged atoms. Sosolik can buy these noble gases in bottles, attach a bottle to a port in the EBIT, and leak in some gas.

But eventually, Sosolik would like to branch out and try, for instance, some metals. After all, if you have a device that can replicate some of what happens in stars, why wouldn’t you study the physics of high-powered phenomena such as solar winds, the fantastical streams of plasma released from the sun?

“Solar wind has iron in it,” Sosolik says. “So how do I get the iron in there?”

To put metals in the mix, he’ll need the extra fittings and controls that came with the system because of the delay. He’ll install another beam line, perpendicular to the first, shoot a beam into the EBIT with a liquid metal ion source, turn it, and load it into the trap. A new hire in physics, Endre Takacs, who has worked the EBIT at NIST, will lead this part of the research.

The potential for working with metals has attracted a group of Australian researchers who plan to come to Clemson to study manganese ions, among others, using the EBIT. In fact, the plan all along has been to make the EBIT what Sosolik calls a user facility, a resource for research teams who can pay the fees, take the training, follow the rules, and do some good science.

Meanwhile, Sosolik’s team is conducting its first experiments with the EBIT, using them to set benchmarks for the equipment but also to learn how materials react to the ions. For example, by studying how various doses of ions affect the kinds of oxides used as a thin film on semiconductors, Sosolik and his collaborators may be able to scale and control the ion doses to engineer the material. When an ion strikes an oxide, he says, it leaves either a crater or a hill. So a well-controlled flow of ions might pattern a surface in predictable and useful ways, for microelectronics, fluid filtration, or some other technology.

As a byproduct of this kind of work, the team can also test materials that might be used in outer space, because the EBIT can simulate the kinds of radiation common there. Sosolik and his coinvestigator, Rod Harrell, submitted a proposal to NASA for a project that would test materials coated with silicon carbide, which is far less sensitive to high-energy radiation than the silicon used in most electronics.

Meanwhile, the team is still learning how to track the many forces and counterforces unleashed inside the EBIT. How many millions, billions, or trillions of ions should they send down the pipe at one time? How do they account for the recoil of electrons that are hitting the walls of the machine? How do they make sure the oxide they’re using for a target doesn’t gain so much positive charge that it repels the very ions sent to shape it?

“The questions are important,” Sosolik says, “not just because they’re the sort of geeky little things that physicists like to chase. The questions would also be important if you wanted to do this in an industrial context.”

Certainly, industrial applications are a goal. So the lab is firmly grounded in the pragmatics of engineering and materials science. But when you’re using a tool that can simulate some of the rarest and most dramatic forces in the universe, you can’t help but think big, now and then. Sosolik has been part of a project, funded by the Defense Advanced Research Projects Agency (DARPA), investigating ways to form diamonds by simulating the forces in exploding stars.

“People have found things like carbonaceous meteorites with pockets of diamond inside them, and inside those pockets they see xenon, little xenon atoms,” Sosolik says. “That probably means that some highly charged xenon came flying in and actually turned a piece of that thing into diamond.”

It’s too early to say, at the moment, whether Sosolik and his team will be making any diamonds, literally or figuratively, any time soon. There’s a lot of hard science to do before the researchers can push the machine to its full potential. But if you’re fortunate enough to land an EBIT, it might just pay to keep your feet on the ground and your head in the stars.

Chad Sosolik is an associate professor of physics and astronomy. James E. Harriss is a research associate in physics. Endre Takacs is an associate professor of physics and astronomy. W. Rod Harrell is an associate professor of electrical and computer engineering. All are in the College of Engineering and Science. Funding for the work described here primarily came from the National Science Foundation and the Defense Advanced Research Projects Agency. Glimpse briefly introduced the EBIT in the Spring 2012 issue, soon after the machine arrived on campus.

Sosolik’s portrait is by Craig Mahaffey.

Shooting with star stuff

The latest cool tool in physics is a machine that replicates forces in the belly of a star. The idea is to harness those forces to develop useful new materials here on Earth.

This marvel of engineering is an electron beam ion trap or EBIT. Clemson has one of six EBITs in the U.S. and the only one outside a national lab or institute. This one brings several advantages. It can recirculate the scarce and costly liquid helium required to supercool its superconducting magnet. (Several older EBITs sit idle because labs can’t afford to keep piping fresh helium into their magnets.) It’s new, with all the latest bells and whistles. It accepts various attachments to expand its versatility. And, of special relevance here at Clemson, it’s been designed to help investigate and develop new materials. Combined with faculty expertise in physics, materials science, and engineering, the EBIT makes Clemson a leader in the race to apply space-age technology.

The illustrations here offer a brief, highly simplified introduction to the EBIT and how it works.

Conceptual illustration of target adapted from McAllister Technical Services. EBIT image courtesy of DREEBIT GmbH.