Reality and the big, fuzzy blah

Neil Caudle

Are engineers creative?

Of course. But don’t expect them to admit it.

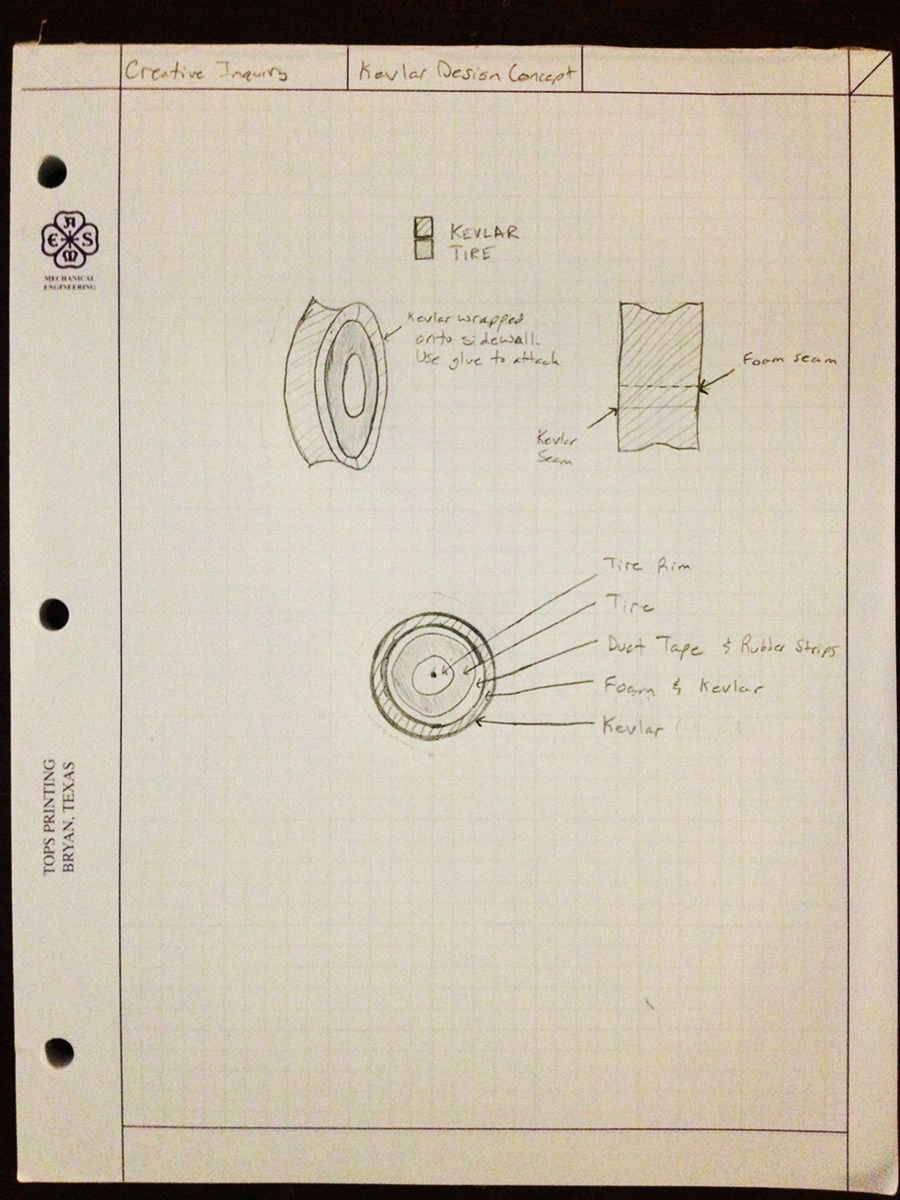

Getting a grip on the rock-studded dust of the moon’s surface means reinventing the wheel. Joshua Summers’ Creative Inquiry team is taking it on. Image courtesy of Zach Satterfield.

One suggestion: Do not use the term science fiction when you talk with Joshua Summers. “It is not science fiction,” he says. “It is engineering fiction.” He has a point. A writer who invents a realm of exotic new technologies play-acts the role of engineer, without the considerable bother of actual reality. “Engineers deal with reality,” Summers says, “and we still have to overcome reality. We have all kinds of physical laws that we have to play within and still achieve things that have never been done before. Engineering is about creating what can be. Science wants to understand what is.”

Reality doesn’t just hand over a hunk of What Can Be without a fight, and Summers and his students are constantly testing the limits of physical laws. This gritty push and shove gets them going, makes them more—dare we say it?—creative.

“We don’t like to use that word,” Summers says, politely.

Why not?

“Because it’s loaded.”

Okay.

“And because other disciplines have staked a claim to it, and we don’t want to fight them for it.”

Okay.

“We tend use the word ideation instead.”

Oh. Okay, then.

Whatever term we apply to the struggle, its goals are simple, as Summers puts them:

2. Build something.

Creativity—ideation—plays a role in both one and two. At the heart of design, Summers says, is an act of synthesis. Sometimes, synthesis means plugging old stuff together in new ways, as when a kid plays with Legos. Other times, there’s something missing, a gap. A kid can make do with a well-chewed wad of bubble-gum; an engineer has to plug the gap with something new.

“That’s when we have to roll back on our understanding of the way the world works in terms of chemistry, physics, and biology,” Summers says. “And we have to work by analogy, by expanding our reach, by moving to a new frame of reference.” The synthesis that leads to creation is the good stuff, the nectar that draws problem solvers into engineering like bees into blossoms. So telling a student that engineering today is all about crunching numbers is a buzz kill. And it just isn’t so.

The Sand Traction team of undergraduate students is testing Kevlar as a material for the treads of lunar rovers. In the photo, Steven O'Shields (right) presents test data to the team during a Tuesday-night work session.

“Crunching numbers is a necessary evil for most of us,” Summers says. “You want to make sure that this new brake system works, so you crunch the numbers. But that’s not why we want to be engineers.”

The personal ambition to create, Summers says, is probably the same for an engineer as it is for a painter or a poet. “Even an artist has a goal,” he says. “The goal may be an emotional evocation, but it’s still a goal. It’s an intentional act.”

Summers’ first and foremost goal is to teach people how to be creative engineers, and he’s in a hurry about it. Our economy—check that, our society—needs thousands of good engineers immediately, if not sooner.

And that’s a tall order.

“Some people say it takes ten thousand hours of experience to become a good engineer,” Summers says. “But we don’t have time to wait for our students to get their ten thousand hours. We have to short-circuit that. We have to make our students competent engineers immediately.”

Folding a burrito

This is risky business, because the stakes are higher than they are for other kinds of creative ventures. Writers, for instance, can struggle for decades to master their craft, and no one’s life is in jeopardy if they don’t get their novels right. With engineers, it’s different.

“Something as small as a bracket on a car can cost people’s lives,” Summers says.

So it is his job, as he sees it, to make junior engineers work as smart as senior engineers. To do so, he and his colleagues have assembled a sizable toolkit of theory and practice to help them school aspiring engineers, not just in the facts they’ll need to know but in the creative problem-solving essential to success.

Summers uses this toolkit to guide his students through what he calls the design space, which includes the problem space and the solution space. Spacey as this might sound, the notions are grounded in pragmatism. Any time engineers attempt to design something new, they have to weigh the merits of each conceivable option, analyzing its problems and potential solutions, its costs and practicality. In the throes of this struggle, designers pinball back and forth until the distinction between problem and solution begins to blur. Things get messy.

“Design space is this big, fuzzy blah,” Summers says, “but I like the challenge of the fuzziness.” He attacks it systematically, weeding out emotions and baseless assumptions.

Consider for example a class project that involved designing a burrito-folding machine. Let’s pause for a moment while you wrap your head around the daunting prospect of inventing a machine that can make a burrito.

Here is how Summers and his students went about it: “First we had to ask, what will this machine have to do? Lots of things: load and position the tortilla, dispense the filling, fold the tortilla over and over and over, eject it, and so on. So what are some of the ways we can accomplish these functions? For every function, you come up with a bunch of different ideas. And we have tools for that, for generating the ideas. Within twenty minutes you can have several million ideas. So then we need other tools to refine and process the ideas.”

To navigate the fuzzy realm of design space, students need the one thing they generally lack: experience. They need not just engineering experience but life experience. Creative people often generate ideas by analogy, and the best engineers cast a wide net in their search for analogues. Even Thomas Alva Edison designed by analogy, applying what he’d learned from the telegraph to his work on the light bulb, for instance.

Summers, whose own resume covers more ground than an engineering-fiction novel, pushes his students to branch out, take a drawing class, study languages, learn to write—absorb as much as they can.

“I’m a big believer in the idea that a variety of experience leads to a variety of understanding,” he says. Reading, he says, is an especially useful shortcut. “When you read, you are indirectly developing experiences. And those will help you look at problems from a different perspective. It will help you reframe things.”

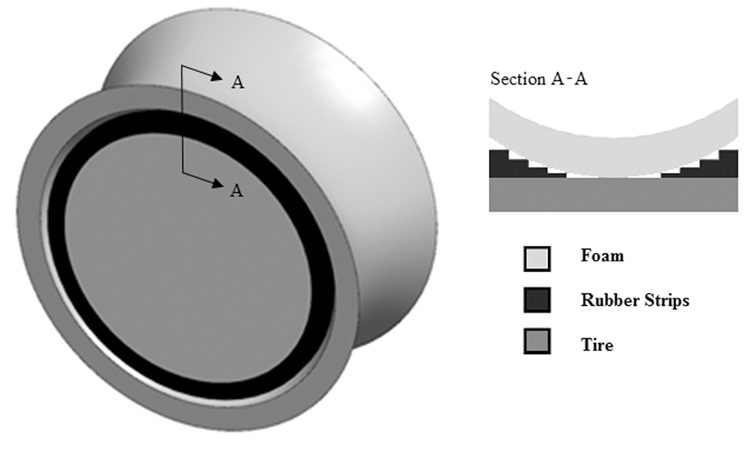

After pencil sketches, the Creative Inquiry team moved to CAD drawings like the one pictured here. Image courtesy of Zach Satterfield.

One of the lessons engineers learn from experience is not to go it alone. Engineering today, Summers says, is decidedly social. Our romantic old notion of a lone inventor tinkering away in his workshop is well nigh obsolete. Today’s engineers, like the mastodon hunters of yore, attack each big, hairy problem as a tribe would, stalking the beast from all sides. “An advantage of engineering as a social activity is that you have not two eyes but twenty eyes looking at a problem,” Summers says.

Twenty eyes are good, but forty might be overkill. For his ideation sessions, Summers assembles a small group of people—five to fifteen in number—who are excited about solving the problem at hand. Depending on the nature of the problem, the team selects one of many “ideation tools,” methods for guiding the group interaction. One such tool is called the Gallery Method.

Each member of the team takes a pad of sticky notes, quickly sketches a bunch of ideas, and sticks them on a wall. The team reacts to each member’s sketches with more sketching.

“The idea is to build on other people’s ideas,” Summers says. “We use a principle called provocative stimuli, which is a way for each person to see something and interpret it differently. So this is one tool. We have lots and lots of tools.”

Whatever the tool of choice, the goal is to arrive at the best ideas as efficiently as possible. But ideas are not the only goal. Dealing with the ever-present risk of failure is another. In both the design space and the building space, engineers set up systems with what Summers calls gates, a series of checks, tests, and tough questions designed to ferret out the flaws. In Summers’ view, failures in the fuzzy world of design space should be expected, not punished. They come with the territory.

Fail early and often

“Our philosophy runs counter to most,” Summers says. “It is fail early and fail often. Engineers cannot be afraid of failure. We have to learn from failure. We have to explore as many ideas as possible. That might include throwing out a hundred bad ideas.”

The Creative Inquiry team tests the durability of their designs in a merry-go-round-like arena where the wheels travel a circle over moon-like soil.

Very often, young engineers wander off track in the thrall of computer-aided design (CAD), a technology that can make even a bad idea look good. At the computer, a student smitten with his own half-baked idea can produce a seductively slick presentation that looks like a valid design.

“This is the biggest obstacle for some of our students,” Summers says. “They fixate. Putting forth that little bit of effort to create an attractive presentation can wed you to the idea, and people will gravitate to it. Better-represented ideas will tend to be selected.”

It’s a tricky balance. On the one hand, engineers working in a social group must communicate ideas, often with models; computers help them crank out the models. On the other hand, chasing a bad idea off through the weeds is a waste of time.

To be fair, it’s not only students who get snowed. Even the most prosaic technology, artfully rendered in CAD, can put stars in a client’s eyes. “We’ve shown pretty representations of a trash truck, and the clients think it’s great,” Summers says. “But they’re totally biased by the representation.”

Summers has studied such problems in the course of his research. For an entire semester in 2007, Dave Veisz, one of Summers’ graduate students, observed a team of student engineers working for Raytheon on a landing gear for an unmanned vehicle.

“When Dave watched the students, he was shocked to find that in the first meeting, kids came with CAD models,” Summers says. There were no preliminary sketches; the students went straight to the computer. And sometimes, they floundered there.

“Dave identified times during the project when students would overcommit to a specific solution because they had spent so much time working on that model,” Summers says.

Back to shop class: In high school, Joshua Summers defied his guidance counselor and signed up for shop. He is still there. Making stuff, he says, takes more than number crunching.

Over the last decade or so, the addictive habit of instant gratification by CAD has found its way into the workplace. Veisz and Summers interviewed faculty members and people in industry, comparing responses from those who were relative newcomers with those who had more than five years of experience.

“The general pattern we discovered was that young industry people and young faculty members saw more value in computer modeling than in sketching,” Summers says. “Older engineers argued that we still need sketching.”

Summers is neither old nor anti-computer. (We had our talk via Skype, while he was in France.) But in his view, sketching by hand helps an engineer test many ideas before settling on the one worth modeling.

“Once you have an idea that you want to model, then the computer gives you a better way to make changes and try things out,” Summers says. “You have to have both, the sketching and the computer.”

Too many students are taught to regard computers as the go-to technology for each and every problem, Summers says. This is like assuming that because a hammer is useful for driving nails it will be great for window-washing, too.

To Summers, a toolkit should include more than a hammer, and an engineer should have more than a one-track mind. Maybe that’s why some of his most successful students have begun as academic misfits, people who’ve had trouble playing the role of dutiful, grade-seeking drone.

“I’ve had some really great luck working with students who had very poor GPAs, and they’ve turned into some of my best graduate students,” Summers says. “When we’re recruiting students to graduate school, I’m looking first for people who are excited and willing to work. Number two, I am looking for people who are willing to ask questions. Those are the two traits.”

Now and then, a student whose hard work hasn’t paid off in high grades will have a breakthrough, a moment when engineering ceases to be an academic slog and suddenly becomes a passion, a drive. “Sometimes, a switch turns on,” Summers says. He likes that switch. He has a passion for it.

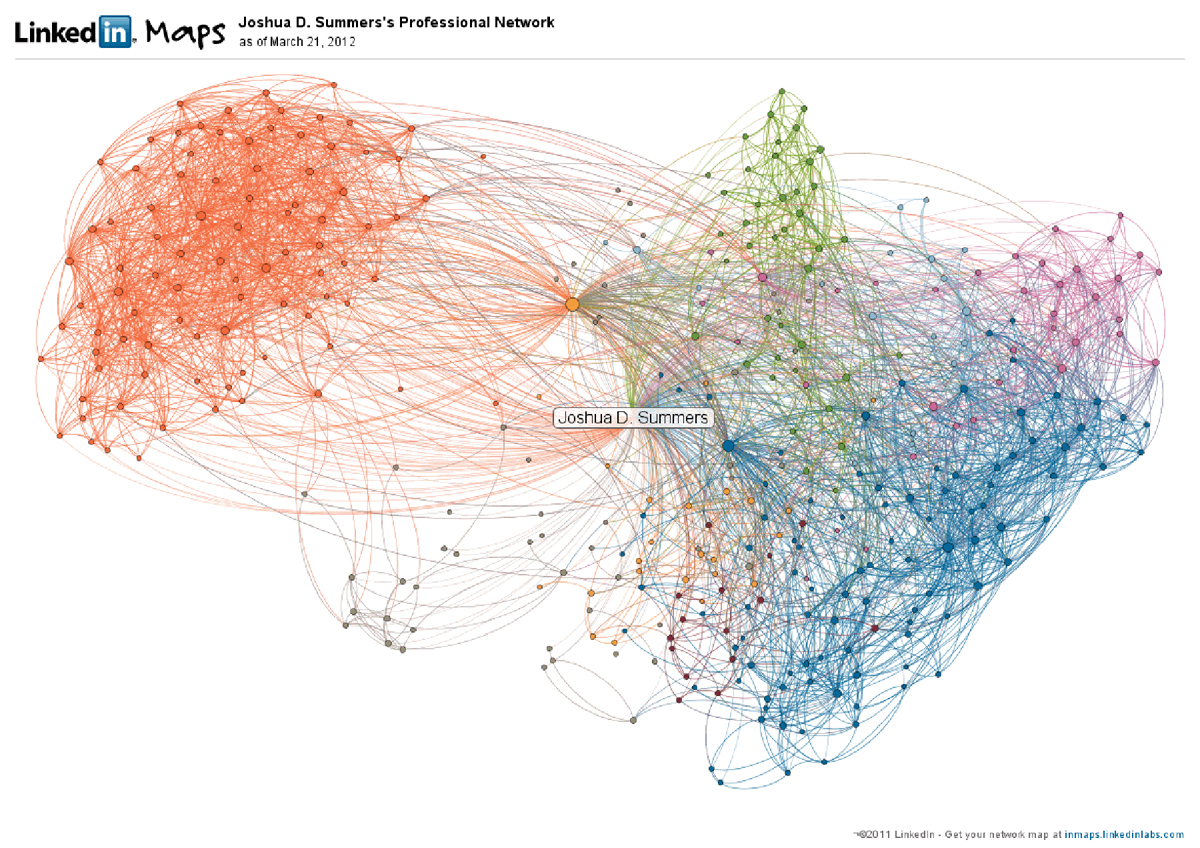

This representation of Joshua Summers's complicated LinkedIn network shows just how social engineering can be.

The parts left over

Summers himself is a kind of misfit, an engineer astray from a family of educators (as in people with education degrees). With all due respect to his kin and their chosen pursuits, Summers doesn’t put much stock in ordinary classroom teaching, if students can’t build stuff with their hands. When I ask him what our society should do to produce more engineers, he has a ready answer.

“When I was in high school,” he says, “the guidance counselor told me not to take shop class. I said, ‘But I want to be an engineer.’ And he said, ‘Engineers only need to know math and science.’ I ignored his advice and took shop class.”

He made the right choice, he says, but that doesn’t mean he learned to be a good mechanic. His wife won’t let him work on the family car because he winds up with leftover parts at the end of the job. But if shop class didn’t make him a mechanic, it did help him appreciate how things are made. “You can’t just sit down at a computer and create something in a vacuum,” he says. “You have to know how to make it. You have to know what it takes.”

Joshua D. Summers is a professor of mechanical engineering and an IDEaS Professor in the College of Engineering and Science, where he codirects the Clemson Engineering Design Applications and Research (CEDAR) group. Dave Veisz is now the director of operations for Maker-Bot, a 3-D printing company.