Material advantage and the power of light

stories and images by Neil Caudle

Fiber optics spread the Internet around the globe, but the science of light is just warming up. And so is the science of rust.

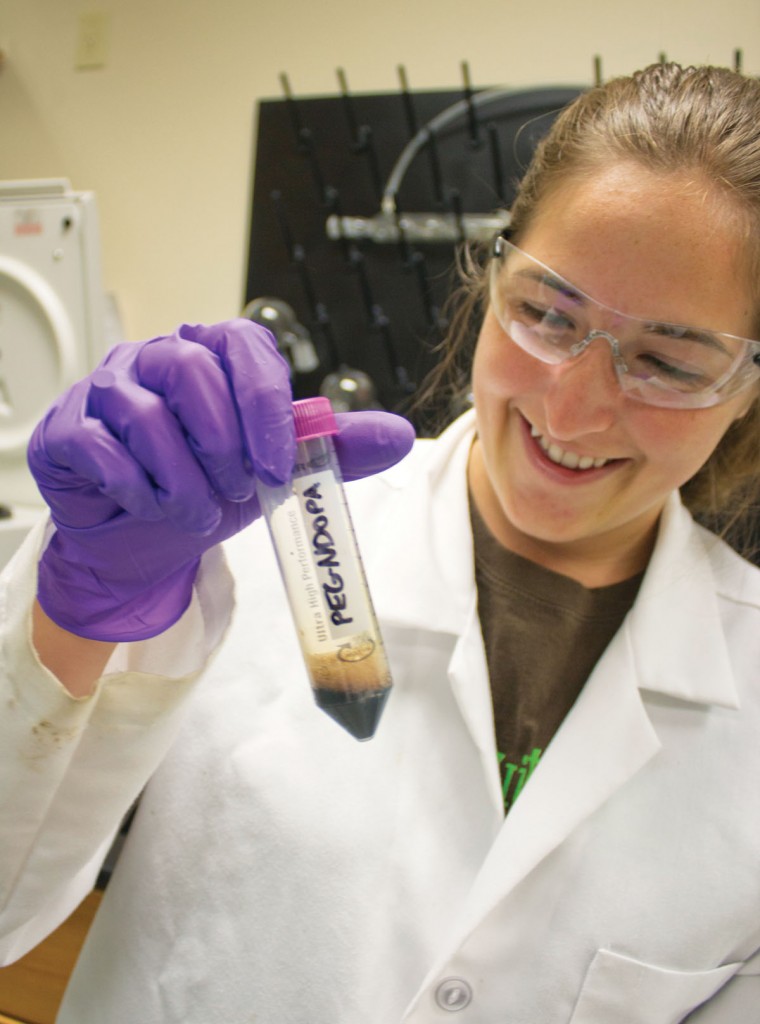

When Maeve Budi hasn’t been home for a while, her father will say she’s been playing with rust.

“No,” she says, “I’ve been working to cure cancer.” As excuses go, this must rank among the all-time best. But Dad, for once, was right; she was playing with rust. Tiny bits of it. Brownish, sludgy slurries of it. This is iron oxide, like the rust on the scissors you left in the rain. Now it stains the white sleeves of her lab coat. And yes, it is fun.

Just four years ago, when she was a freshman, Budi had never imagined a future in rust. And the idea that rust would fight cancer? No way. Rust is a cancer, right? A cancer of metal?

But take a few bits of that rust, form them into tiny particles, coat them with precisely the right chemical concoction, and direct them toward a tumor, where they penetrate the cells and do not assail the patient’s body with toxic drugs or risky radiation. Instead, pass a mild wave of radio-frequency magnetic energy through the tumor to excite the iron atoms and heat the particles just enough to kill the cancer cells, and only the cancer cells, with zero damage to the healthy tissues around them. You would kill cancer with rust. And for an undergraduate student keen on doing something real with her life, that possibility was too cool for words.

My first contact with Budi was her voice, as I passed in the hall. She was inside an office, making her case to a couple of men who weren’t ready to buy it. Someone would reel off a series of numbers; someone would hmmm; all would go silent a moment, then riff on what-ifs and yes-buts. No one was angry; no one was tense. But I knew there was plenty at stake.

So I crashed the party, leaned against a wall in a second-floor office of the Advanced Materials Research Laboratory (AMRL), and listened. Budi’s professor, Thompson Mefford, was propped back in his chair, a foot on the rim of his desk, lobbing questions. Steven “Moose” Saville, who is finishing his Ph.D. under Mefford, stood nearby with his arms crossed, genial but imposing, like the second cop in a tough interrogation. Budi held her own, walking them through an experiment, reporting what she’d found, venturing an explanation.

The team, which also uses nanoparticles to develop new optical materials, had been testing two methods for coating iron oxide particles with chemicals that could anchor a polymer to their surfaces. Eventually, if things went according to plan, the polymer and its chemical payload would help guide the particles into cancer cells. One of the anchors, nitro dopamine, had worked as expected, but the other, a phosphate, had performed better than was theoretically possible. The team did not trust the data.

In the chair beside Budi, Mellissa Stimson, a rising senior, was tracking the debate. Stimson, who’s in line for more rust now that Budi has graduated, plans a career in science policy. She was in the lab to learn, firsthand, how science works. Today, she was learning how scientists gang-tackle a problem and wrestle it to the ground.

Not much of their talk about the phosphate-anchoring problem would have made sense around the dinner table, back home. Budi and Stimson had come away to college and stepped inside a strange new world, a world with its own special language, and it suited them both. Budi is headed next to Florida to work on a Ph.D. She aspires to be a scientist. Here is a clue about her chances: School is out for the summer and she is still in the lab. She has finished her classwork, bagged her diploma. But she is not at the beach with her friends. She is not at home with Mom and Dad. She is playing with rust.

Trouble is, not enough students like Budi and Stimson are finding their way to the lab. Every day, we read about the critical shortage of American scientists and engineers. Somehow, the youth of today, agog in the digital dreamscape of futuristic marvels, are not yet awake to the fact that they themselves could make these dreams come true.

The idea, around here, is to wake them.

If you build it, they will come.

From Clemson’s main campus, take a two-lane blacktop south through a patchwork of cropland, woods, and fields. Several turns later, your GPS may send you to the loading dock, as mine did. Find your way around a wooded slope and park in front of Clemson’s field of dreams, a LEED silver building (certifying its sustainable design) that houses, among other things, eight thousand square feet of optics labs. There was no voice from a cornfield, but an ultramodern laboratory building and research park have materialized, here in the middle of nowhere.

For a time, some people thought Clemson was delusional to gamble on a research park with an optics lab at its core. Around the nation there were already hundreds of research parks, many with optics labs, and the most successful of these were usually near high-tech hotspots such as Boston and Silicon Valley. Was Clemson ready to play in that league?

Apparently, yes. Now, twelve years after its formal inception, the Center for Optical Materials Science and Engineering Technologies (COMSET) includes thirty faculty members publishing sixty to seventy journal articles a year. Breakthroughs from COMSET make the covers of high-profile journals. Better yet, from a scientist’s point of view, citations of COMSET papers may soon top a thousand—per year. Because citations indicate influence, this is a sizeable claim in the marketplace for knowledge.

Coffee, beer, and light

John Ballato seems too young to serve as the resident historian of anything, but today he fills that function for COMSET, which he directs. In 1997, Ballato, a brand-new assistant professor in materials science and engineering, showed up for orientation at Clemson and settled into his seat beside another newcomer, David Carroll from physics. In the course of that session he and Carroll discovered, Ballato says, “a common passion for coffee, beer, and light.” (The order of priority changed with the time of day.)

Very soon, Ballato and Carroll were crossing departmental borders, sharing equipment and know-how. “I needed lasers,” Ballato says; “Dave knew how to run them better. He needed chemistry; I knew how to do the chemistry better. I would buy something and put it in Dave’s lab; he would buy something and put it in my lab, and our students would come back and forth.”

They laugh about it today, but at the time their disregard for turf unsettled a few senior colleagues. “We would do,” Ballato says, “unheard-of things.”

Carroll eventually moved on to direct a research center at Wake Forest University, but not before he and Ballato had accumulated a cohort of like-minded insurgents who also valued coffee, beer, and light. Unlike most people working in optics, this group was not inventing gadgets for the telecommunications industry; they were interested in something more fundamental. They were studying light, yes, but light in relation to materials.

“The nice thing about materials is that you may design them for one thing, but you may be able to tweak them and make another thing,” Ballato says. This is why the lab’s research in optical materials has led to technologies with diverse applications in defense, telecommunications, and medicine—from killing cancer cells to stopping missiles. The team’s expertise with materials has given them an edge.

“There’s a ton of competition out there,” Ballato says, “but the vast majority of these programs have physicists or electrical engineers and don’t know anything about materials. So they came to us.”

During the 1980s and ’90s, telecommunications had claimed the big money and many top optical scientists and engineers. For a time, the military had trouble finding the talent it needed to develop new optics-based hardware. The Clemson team saw an opening and made a name for itself at the Pentagon before the telecommunications boom began to wane.

“The military had an unmet need,” Ballato says, “and if you’re working with the military, you have to be domestic. So the foreign competition goes away. The military and security niche is still very competitive, but it’s easier to get ahead once you’re established. We had good people, and we had good contacts, and we were able to jump ahead of lots of other programs.”

Glass slippers

Materials science is a field that has sometimes toiled in obscurity. Practically speaking, this makes no sense, because the material we use to build a thing can dictate its performance. The information age, for example, might never have dawned without silicon for making semiconductors, or without silicon’s oxide, silica, which mediates the flow of electrons on computer chips and also happens to be the main ingredient in sand and glass. By learning how to purify silica and form it into long, hair-like fibers, scientists and engineers developed the fiber-optic cables that crisscross continents and oceans, connecting billions of people.

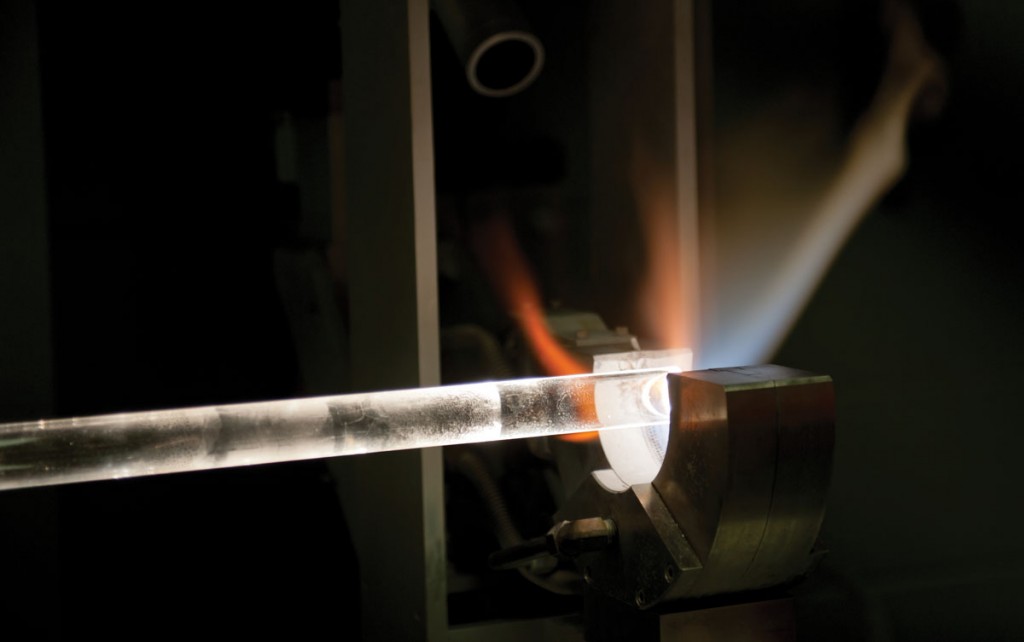

Glowing with light from a gas flame, a glass rod takes shape in Clemson’s Advanced Materials Research Laboratory. When the rod is ready, research staff will install it in a draw tower, a behemoth of furnaces and highprecision equipment that will spin the rod into purified optical fiber. Researchers use optical fiber to develop new technologies with applications ranging from cancer treatment to missile defense.

The Internet dances in slippers of glass.

But the dancing has only begun. If the world’s second industrial revolution harnessed the electron, the third may be driven by photons. In every corner of the new economy, from manufacturing to medicine to military weapons, people are grasping the power of light. But applying that power means finding new materials and new ways to use the ones we have.

In this quest, COMSET offers a material advantage. Ballato’s own research, for example, was finding ways to improve the optical properties of glass fibers by reducing impurities and by “doping” glass with properties that amplify or tailor light. But in Ballato’s view too much of the research funding, public and private, still went elsewhere—toward the devices themselves and not toward the stuff from which the devices were made. “The money is usually downstream, with the devices,” Ballato says. “You’re making something you can put on a program manager’s desk, press a button and zap a wall.”

To compete, COMSET had to zap a few walls.

It formed partnerships with institutions and companies that made lasers and other devices. This worked fine, but the money was still leaving Clemson. “We were shipping out well over a million dollars a year,” he says. “We went to our administration and said, ‘Wouldn’t you rather that the money stay here, to create a structure, educate students, and build visibility—all the things research can do?’”

The administration said yes and invested in four new positions for what Ballato calls “devicey” people. And the first of those hires would bring plenty of zap.

A bigger pipe

When Liang Dong was a boy in China, he knew that he wanted to do something technical when he grew up. Like every little boy, he played in the sunshine and read by the light of a lamp, but he never imagined that he would one day take up the light in his hands, concentrate it, guide it, and send it blazing with such force that it could blast through an incoming missile, destroying it in flight. Now it’s his job to help make that possible. And he begins with one deceptively simple material: glass.

The skinny glass threads in a fiber-optic cable are adept at piping photons for thousands of miles to beam our emails and spreadsheets and viral videos around the globe. But if you want a fiber laser strong enough to stop a missile, you will need a bigger pipe—one that can carry not a few watts but thousands.

For a half century, the U.S. Department of Defense (DoD) has been searching for that kind of power. But conventional lasers relied on mirrors and crystals, and bulky mechanical parts that had to be perfectly aligned for the laser to work. This was not a technology you could mount in a spacecraft or fighter jet. The advent of fiber lasers, coincidentally by Ballato’s former advisor and frequent collaborator, Elias Snitzer, suggested a way to jettison some hardware and simplify the system. In a fiber laser, a small “pump” converts electricity into concentrated light and sends it down a fiber that can guide the beam towards a target. The fiber laser’s slender geometry allows excess heat to move quickly to surface and away—a key to high-power operation.

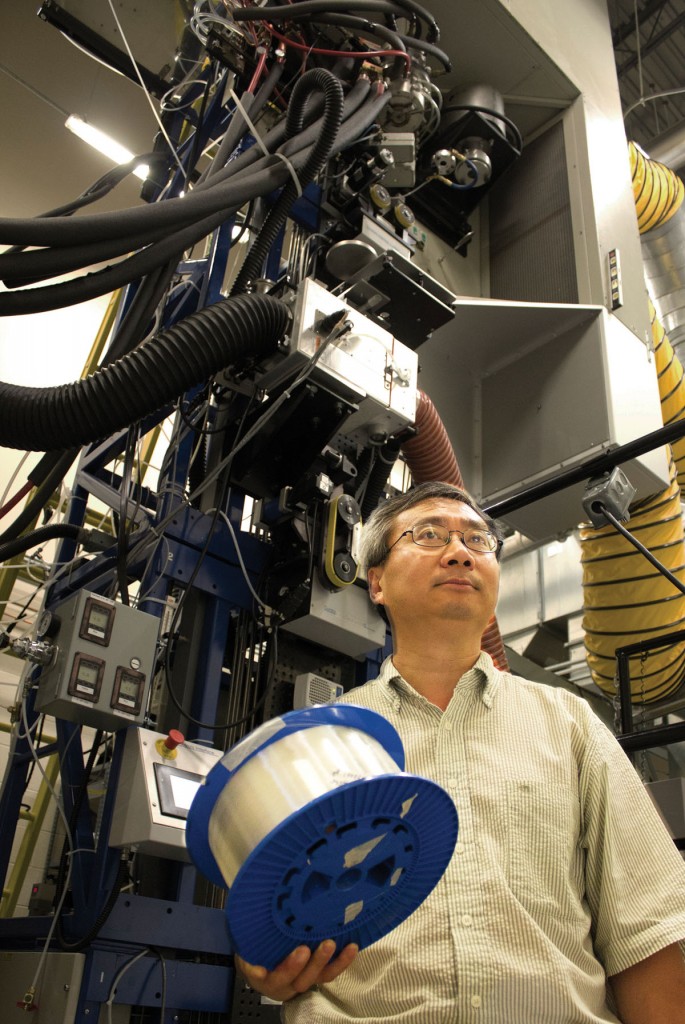

Liang Dong, at the draw tower, holds a spool with twenty or thirty kilometers of optical fiber produced in the lab. “Before we had this kind of fiber, copper was the material we used for telecommunications,” he says. “I would not be able to hold a twenty-kilometer spool of copper.”

Liang Dong, at the draw tower, holds a spool with twenty or thirty kilometers of optical fiber produced in the lab. “Before we had this kind of fiber, copper was the material we used for telecommunications,” he says. “I would not be able to hold a twenty-kilometer spool of copper.”During the 2000s, factories began using beefed-up fiber lasers as machining tools, slicing and piercing metal at high speed, and the tools were often mounted several feet or yards away, never touching the materials.

In his corporate job making optical fibers, Liang Dong could see that the DoD wanted something that closely resembled what industry already possessed: a remote machining operation. The time seemed right to leave industry and go after the long-elusive laser. So two years ago Dong joined the faculty in electrical and computer engineering at Clemson, built a team at COMSET, and went to work on a new generation of optical fibers.

“For me, this is a technical challenge that is way beyond what the commercial world is looking for,” Dong says. It is, however, exactly what the DoD is looking for: a powerful, long-range laser that strikes with the speed of light.

To understand how such a laser would work, it helps to recall a bit of basic physics. Light is electromagnetic radiation, like radio waves or microwaves, but its waves wiggle faster. A laser beam is highly concentrated light. When you direct that light against a surface, its electromagnetic field can rip apart the electrons that bind matter together. This is called ablation, and it is the same process that reshapes a human cornea during laser eye surgery.

In combat, lasers mounted on military platforms could intercept and destroy rocket-propelled grenades and heat-seeking missiles. But the potential for using lasers is even greater in space-based missile-defense systems, Dong says, because space has no atmosphere to interfere with the beam. A laser beam could travel thousands of miles and open a hole in a missile traveling several thousand miles an hour.

But ablation, which would make the laser a devastating weapon, also makes a big fiber laser hard to build. As the power level rises, photons begin to pull silica’s electrons out of orbit, degrading the light. And various other bugaboos, including sound waves, disturb the flow. Dong had to solve these problems, if he hoped to succeed.

Dong has an instinct for isolating, with laser-like precision, a technology’s core issue. As he saw it, the fiber itself was the core technology, as the CPU was the core of a computer. Everything else was peripheral. The power supply, the pump, the hardware for mounting and firing—DoD and its contractors could handle all of that. The limiting factor was fiber. “There’s a lot of people working on lasers in the DoD labs, and they are limited by the fiber they have,” Dong says. “If this works for them, they can deliver a lot more power. So that’s the goal.”

No single fiber could handle the power a weapon requires, and neither could the simple concentric patterns of fibers the telecom industry used in its bundles. Dong began to design experimental bundles with various types and sizes of carefully crafted glass rods to merge multiple channels to create a uniform beam. This was a very different problem from what he’d faced in telecommunications.

“We’re not making kilometers of this stuff,” Dong says. “We’ll just be using a few meters. That means we can have a much larger core size while keeping the beam quality good.”

On his computer, Dong shows me the kind of pattern he prizes in a laser beam: an intense but uniform glow at the center, dimming neatly at the margins. The beam of light itself shows a radiant simplicity, but Dong’s team cannot achieve that simplicity without technical complexity and near-perfect clarity—in the work and in the glass. The fibers he makes are so different from the standard that he had to create a completely different fabrication process for it. “You cannot get this kind of fiber commercially anywhere,” he says. “In fact, this is the only place in the world where we can make the kind of glass we want.”

Knobs to tweak

For Dong, the process of creating new optical fiber must be managed as a whole, with each step informing the rest. “We have people looking at designs; we have people looking at material and a whole new process for making the fiber itself and pulling the different glass structures together. And the testing of those fibers is also very different, because the guiding principles are different from commercial fibers.”

To make new fibers, the team uses a twenty-foot industrial monster—a draw tower—available in only three other U.S. university labs, though none is like the one at Clemson. With three interchangeable furnaces capable of up to four thousand degrees Fahrenheit, the tower can produce a continuous thread of highly purified glass.

Purity is key, Dong says, because even tiny flaws would compromise the light. “We start with a liquid and purify it multiple times, but even with those steps you still get parts per million of impurities, and we really need to keep those impurities to the parts-per-billion level,” Dong says. In a final step analogous to distilling water, the team heats the liquid and captures its purified vapor to make the glass that ultimately gets drawn in the tower.

The biggest fibers require a slow buildup of glass. In a room near the draw tower, the team uses a high-tech lathe to deposit layer after layer of material from gases and liquids bubbling into the device. The resulting concentric rings of glass confine and guide light in the fiber.

Dong shows me one of the team’s schematic designs, a sectional diagram with a pattern that seems organic, like the specialized cells in the stem of a plant. The center will contain a glass doped with rare earth ions that intensify light. Another glass in the array is black, an anti-guide from which no light can escape.

“These are all derived from silica glass, but with small alterations that enable us to do what we need to do,” Dong says. “So we do have, on the materials side, some knobs we can tweak.”

The next wave

To create a new design, Dong trusts his experience and the principles he has internalized over many years. In the 1980s when in England working on his Ph.D., he studied the early development of optical fibers for telecommunications, which in those days meant landlines for telephones.

“A professor told me, ‘This is a dead end. Soon everybody will be able to talk on the telephone twenty-four hours a day, and one single fiber will carry all of that information for the whole country.’” But then the Internet came along and changed the whole picture. Now the demand for bandwidth is so high that it pushes the limits of a capacity that once seemed almost unlimited.

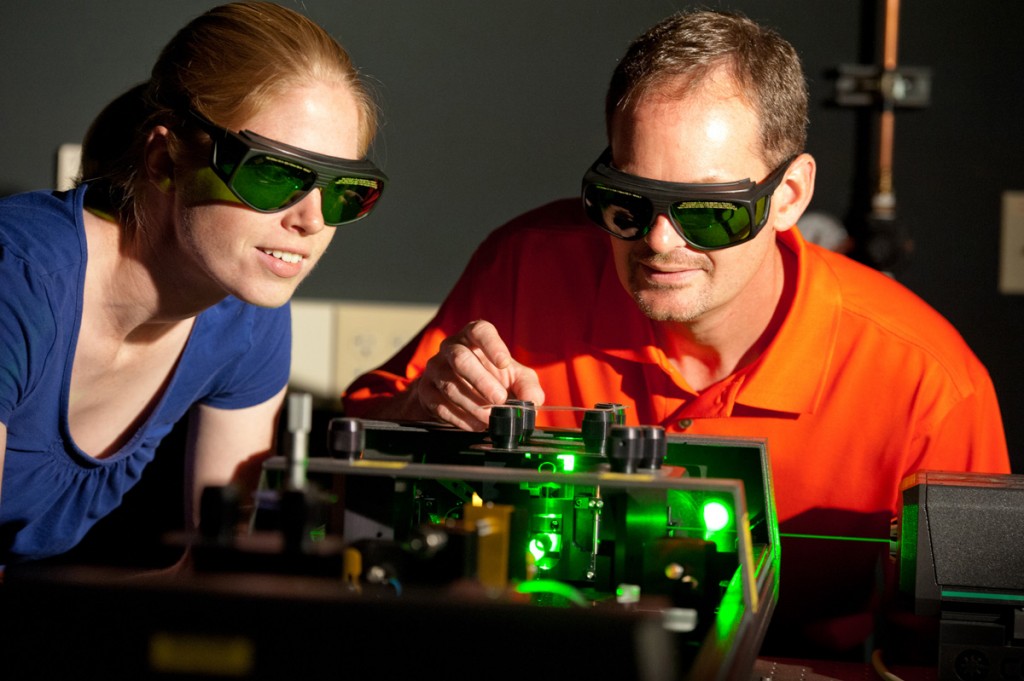

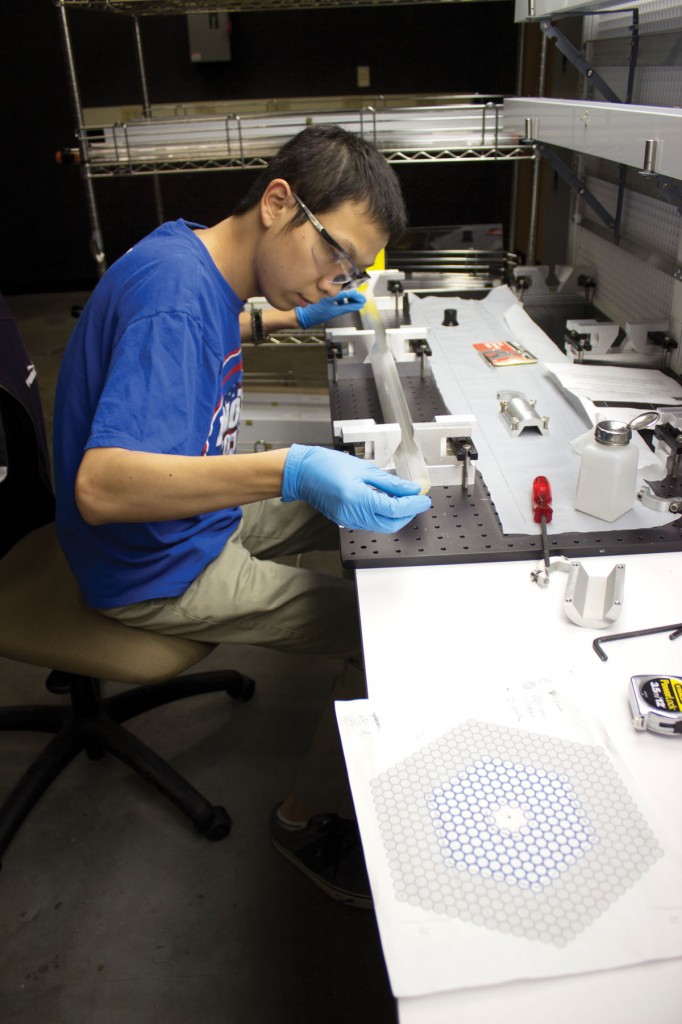

Graduate student Guangcheng Gu assembles a large fiber laser using a pattern designed by Liang Dong.

Graduate student Guangcheng Gu assembles a large fiber laser using a pattern designed by Liang Dong.Today, Dong is working once again in the early surge of fiber’s next big wave.

“My experience has been both in fabrication and design, and the way I see it the two have to interact closely,” he says. “So when I’m looking at a design I am thinking about a range of things: Can this be made? Can this be used practically? Can this be made easily with the tolerances we need? Are there simpler ways of doing this? Once we have a concept, that’s when we go to a computer and say, ‘Okay, how well will this work?’ And the computer can help us identify the precise parameters.”

For now, Dong’s team will design, fabricate, and test fiber lasers up to several hundred watts of power, and the prototypes will go to DoD labs and defense contractors such as Northrup Grumman. After that, the next step will be to make a much larger core capable of handling kilowatts of power. Dong is already conducting theoretical studies to sort out the baffling physics at that level of power. U.S. military labs will do the testing of the kilowatt-size lasers, when the time comes.

Dong says that no other organization, in industry or academia, offered him the tools and opportunity to pull all of this together in one place—the theory, design, fabrication, and testing of very high-power fiber lasers. “We’ve gone where nobody else has been,” he says. “It’s not the typical university approach, but if you can get this to work, that gives you a very strong competitive advantage, because it would be very difficult for someone else to duplicate this whole chain of technology.”

As a natural teacher who rewards each question with a patient, thoughtful answer, Dong wants young people to know just how bright the future is, not just at COMSET, but in optics and photonics, fields in which demand for talent far exceeds supply, in which many of the best discoveries are yet to be made.

“We have these technologies,” he says, “and we know some of what they can do, but we don’t yet know everything they can do. There are many opportunities, and many new problems to solve.”

Not just washing beakers

Which brings us back to students. Maeve Budi continued to work in Thompson Mefford’s lab in the AMRL until her apartment lease ran out at the end of May. By then the team had solved the mystery of the suspiciously perfect results, turning up an error in the data. “We ran the procedure again and managed to attach the phosphate just fine,” Budi says. “I would like to have done this multiple times, to make sure, but I ran out of time. We’ve set it up so that Melissa or someone else can continue the work.”

Budi and Stimson, who have both been tour guides for incoming freshman interested in engineering, urge new students to give research a try. “When I first came to the lab, I thought I’d be washing the beakers,” Budi says. “I was really surprised when I was actually handed things to do, and told, ‘All right, I want you to make this.’ Not only can you figure out a problem and solve it; you can decide what you think is a problem. That is very rewarding.”

This is what Eric Johnson has to explain, outside of work. But what he does make, with his team of savvy students, takes vision.

His was not the usual path to a job fighting cancer. Stephen Foulger was a California dude, a surfer and gear head who built motorcycles.

For now, we can introduce you to only a few of the people at COMSET, and we’ll have to save a number of researchers for issues to come. Or visit the COMSET website.

Roger Stolen, an optics researcher at COMSET whose work was not covered in this article, has recently been elected to the National Academy of Engineering for his contributions to fiber nonlinear optics and invention of polarization preserving fiber.

Roger Stolen, an optics researcher at COMSET whose work was not covered in this article, has recently been elected to the National Academy of Engineering for his contributions to fiber nonlinear optics and invention of polarization preserving fiber.

The National Academy of Engineering (NAE) is a nonprofit, private institution that promotes innovative engineering and provides advice to the federal government. NAE is a member of the National Academies, established in 1863 by President Lincoln, to investigate matters of art and science.

If you want to learn more about it, view him at the National Academy of Engineering website.

John Ballato is a professor of materials science and engineering and a professor of electrical and computer engineering in the College of Engineering and Science. He is also director of the Center for Optical Materials Science and Engineering Technologies (COMSET), which is a South Carolina Research Center of Economic Excellence. Liang Dong is an associate professor of electrical and computer engineering.

The Office of Technology Transfer in the Clemson University Research Foundation has filed patent applications for several of John Ballato’s inventions and for a Liang Dong design of a large-core, high-power laser.