Wrapping up food safety

Anna Simon

Edible communion cup or a pathogen-sensing film, the goal is saving lives.

Paul Dawson rummages through a desk drawer and finds, in a plastic sandwich bag, an edible communion cup made mainly of wheat flour. The cup is a prototype developed in Clemson research labs about seven years ago, after missionaries working in anti-Christian areas asked for a self-contained package that included bread as a cup with wine or grape juice sealed inside. The idea: Leave no evidence behind after taking communion.

Even here at home, lives can depend on the right kind of package. The Centers for Disease Control reports about 1,600 cases annually of listeriosis, a food-borne illness caused by the deadly Listeria monocytogenes bacteria. A 2002 outbreak associated with turkey deli meat caused fifty-four illnesses, eight deaths, and three fetal deaths, according to the CDC. An outbreak in 2012 associated with an imported ricotta cheese caused twenty hospitalizations and at least two deaths. The right package, Dawson says, can block contamination and help prevent illness and death.

“Packaging’s role in food safety has been primarily as a barrier to prevent contamination, but that role has been evolving,” Dawson says. “This includes the label, which now gives proper handling guidelines and cooking directions. The package label has an expiration date that roughly informs the consumer of product shelf life. In the future the package will become more interactive with the food, actively eliminating microorganisms or signaling to consumers that harmful toxins or pathogens are present or have formed in food.”

Dawson is nationally known for debunking the five-second rule about eating dropped food (don’t risk it) and for warning that “double dipping” with shared chips and dip is a practice that spreads germs. At the moment, Dawson and his collaborators—Clemson chemistry professor Bill Pennington and Furman University chemistry professor Tim Hanks—are working on smart food packaging with embedded sensors that change color to warn of contamination by bacteria such as Salmonella or E. coli, both of which can cause food-borne illness. The team is also developing smart bandages that monitor the condition of wounds.

Canary in a coal mine

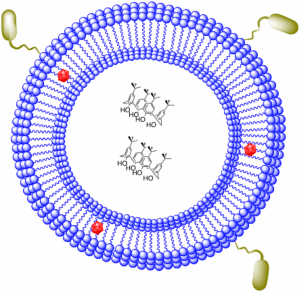

The smart bandages and packaging use liposomes, which are tiny bubble-like vesicles made of lipids (natural molecules that include fats). The liposomes, which measure about 150 nanometers in diameter, are far too small to be seen with the naked eye, but, like a canary in a coal mine, they can warn of pathogens in food or of infection in wounds.

The liposome’s structure gives it potential as a multifunction device, Dawson says. Fluorophores (shown in red) are fluorescent chemical compounds that can re-emit light when excited by a cell-disrupting intruder, an imact, a temper ture shift, or various other changes.

To use liposomes as sensors, researchers embed the hollow spheres in gels or films and design them to change color in the presence of a specific threat. “Looking five or ten years down the road, there are several ways these could be used,” Dawson says. Rinse water used in processing salad greens could be passed through a filter to instantly monitor sanitation of the product, Dawson says. Or cotton swabs could be impregnated with liposomes that change color like litmus paper to check the safety of food and the cleanliness of food preparation areas at home, in stores, and in restaurants.

Dawson, Pennington, and Hanks are excited about the possibilities. “We can incorporate the sensors into packaging or use them to test food-preparation services or food-processing instruments,” Pennington says. He’s already talking to industry about bandages containing liposomes that change color to warn of infection or other changes in wound condition. The researchers start with a synthesized fatty acid mixture processed so that it forms a membrane. An ink-jet printer sprays the fatty acid into water and the mixture curls up into hollow balls as it hits the water. The synthesized compound can be designed to change color in the presence of specific substances. For example, it can be designed to interact with E. coli but not Salmonella.

“We can build specificity into the color-changing process,” Pennington says. Similar technologies are already on the market but are not widely used or recognized because of the expense and difficulty of making the product, Pennington says. He is working on ways to make the process more cost effective on the industrial scale.

Film school

As Dawson and company work on their sensors, other Clemson researchers and their students develop new films that could extend shelf life, reduce spoilage, and eliminate bacterial invasion in packaged foods. Kay Cooksey, an expert in microbe-fighting films, hopes to see the fruit of her graduate students’ labor on grocery shelves in five years or so. Cooksey’s team coats film for packaging meats with natural antimicrobial materials such as nisin, which is produced by bacteria and is already in commercial use by the dairy industry to extend the life of cheese.

Some film samples Cooksey pulls from the cardboard boxes feel nubby; others are slightly sticky to the touch. Some are fairly transparent; others are cloudy. The texture and appearance must be refined to be acceptable to consumers, she says. And the cost of production must be economical so that the packaging doesn’t add to the cost of the food product inside.

Cooksey is targeting industries that produce ready-to-eat sandwich and deli meats. Slicing meats can introduce contamination, Cooksey says.

Antimicrobial packaging adds an extra measure of protection to reduce spoilage, extend shelf life, and eliminate pathogens such as Listeria. The packaging would also reduce waste as less spoiled food would be thrown away, she says, and that could save money for consumers and producers.

Green chicken

Cooksey’s research has spanned a decade, and, like most scientists, she learns as much from what doesn’t work as from what does. An early experiment using chlorine dioxide did a good job of eliminating bacteria but turned chicken green. Disappointed and a little grossed out, the team went back to the drawing board. “Negative results aren’t bad,” Cooksey says. “They just tell you what you can’t do. You have to change the focus a little bit, but don’t quit.”

Paul Dawson’s lab uses liposomes as sensors that can react to food-borne pathogens and other threats by changing color. The vial on the left contains a phenylalanine liposome treated with Salmonella. On the right, the liposome has been treated with E. coli. The vial in the middle was not treated.

The current challenge is heat. Making coated film takes heat. Nisin breaks down under heat and becomes less effective. Students working under Cooksey and Amod Ogale, the director of Clemson’s Center for Advanced Engineering Fibers and Films (CAEFF), are seeking the optimal combination of heat and other factors in processing the product.

Ogale likens chemical engineering to working in a kitchen. The quality of a batch of brownies depends on the combination of ingredients, amount of heat, baking time, and even the type of baking pan used.

But lab conditions are far more extreme than those in the kitchen at home, Ogale says. Equipment in the CAEFF labs is a smaller version of that found in industry and can use heat and pressure as much as ten times greater than those of home ovens and pressure cookers.

Not all of packaging science is directed toward food. Ogale’s group also makes fiber for use in absorbent, disposable hygiene products. By mixing soybean flour and plastics, the team creates a fiber that combines the beneficial properties of both materials.

“That’s what smart materials are,” Ogale says. “Smart materials have to serve several functions.”

Like his colleagues in packaging science, Ogale starts small in the lab but aims for a much larger, industrial scale. The goal is not just a new material but also a practical process for manufacturing it successfully. “Otherwise,” he says, “so many research ideas are born and die.”

Transferring knowledge developed in university labs “into something that changes people’s lives is a pretty complex process,” says Jack Miley, a chemist and retired director of research and development for the chemical division of the Spartanburg-headquartered Milliken & Company in South Carolina. The division has helped its customers develop numerous food-packaging applications using Milliken additives and has a small but growing medical products group. Milliken is “monitoring a lot of different things at Clemson because some of it is pretty close. We would love to have something come to fruition that would work commercially for us,” Miley says. “There are lots of kinds of innovation. The breakthrough ones that matter to somebody a lot are what you want to buy. That’s what you are looking for, but it’s really hard to find.”

Paul Dawson is a professor of food science in the Department of Food, Nutrition, and Packaging Sciences, College of Agriculture, Forestry, and Life Sciences. Kay Cooksey is a professor and the Cryovac Endowed Chair in the Department of Food, Nutrition, and Packaging Sciences. Amod Ogale is the director of Clemson’s Center for Advanced Engineering Fibers and Films and a professor in the Department of Chemical and Biomolecular Engineering, College of Engineering and Science. William T. Pennington is a professor in the Department of Chemistry, College of Engineering and Science. Anna Simon is a freelance writer based near Pendleton, South Carolina. Images courtesy of Bill Pennington, Clemson University, and Tim Hanks, Furman University.